Inventory management is not merely the stored goods, but also to a defensive strategy in the chain operated business accounting. A process inventory less effective will entail a series of implications: inventory discrepancies, delayed orders, loss, cost control, accounting data inaccuracies. This is the reason that many businesses struggling in the optimal cash flow, supply – demand balance, even loss of competitive advantage.

Apply process warehouse management according to ISO is a strategic move to help enterprises standardize the entire process of storage – import – inventory – record accounting. This is not just a matter of process, but also is committed to enhancing the management capacity, financial control, operate, accurate to each number on the books.

1. Process warehouse management according to what is ISO?

Concept overview

Process warehouse management according to ISO is a system of steps, rules, methods are built based on the ISO international to ensure the warehouse is operated in a professional, efficient, consistent, and seamless connection with the accounting system.

Different way to do the traditional capital depends on the experience of personnel, the process according to ISO requires all activities from the import – export – storage – inventory – accounting entries must have rules, forms, tools, strict control, ensure transparency, can audit trace.

The ISO common in warehouse management

Businesses can apply one or combine multiple ISO depending on the objectives, areas of activity:

- ISO 9001:2015 – quality management System quality (most common, used to standardize processes, forms, regulations, quality control, input inventory).

- ISO 14001:2015 – environmental Management (in accordance with business production are factors cargo handling affect the environment).

- ISO 22000:2018 – food Safety (applied in the food industry – stock should comply with storage conditions, strict).

- ISO 45001:2018 – health Safety professional (for warehouse, machinery, forklift, heavy goods).

The role of ISO in connection logistics - accounting

Process warehouse management according to ISO not only to optimal process inventory but also generate reliable data for the accounting department. Specific:

- Export – import repository according to the form ISO will ensure the accuracy, consistency, avoid errors when accounted for in the accounts as TK 152 (Raw material), TK 153 (tools), TK 156 (goods).

- Logistics data standardization will help automate reports, inventory reports, the price of capital, creating the foundation for the cost analysis, cash flow management, audit.

- Sync with accounting software helps to retrieve data quickly, limiting the input manually, reduce errors arising.

According to research conducted by APQC year 2024, the business application process inventory management according to ISO was:

- Reduce 35% error data entry, inventory compared to manual processes.

- Increased by 28% the speed of processing orders, thanks workflow, clear, form standardized.

- Shorten time inventory periodically from 3 days down to 1 – 1.5 days.

Read more:

- Solution warehouse management software and supplies help optimize process storage

- Export warehouse material for manufacturing products properly defining the plan

- Description the work of inventory accounting details for candidates new to the profession

2. Detail the steps in the process, warehouse management according to ISO

When implementing inventory management according to ISO, enterprises need to build a workflow repository, it phased standardized form, the document specified responsibilities and powers, method of disposal. Here are the 5 most important steps:

Step 1. Receipt, check the goods enter the warehouse

The warehouse according to the ISO standard does not simply “get and keep”, which is a strict process consists of many steps, quality control, stock from.

Process warehouse management according to ISO details:

- Goods receipt invoice, delivery notes, contracts from suppliers.

- Parts warehouse combined with accounting inspection of quality, quantity, expiry date (if any), collated with orders.

- Recorded by warehousing form ISO, update the data into the accounting system.

Benefits with accounting warehouse:

- Lose the status of “in stock but not on the window”

- Make sure the account right from the first step (TK 152, TK 156)

Step 2. Sorting, arrange, preserve goods in process inventory management according to ISO

The layout of goods in the warehouse according to the standard ISO not only help manage convenient, but also ensure safety, making it easy to retrieve.

Principles apply:

- 5S + FIFO/FEFO: clean, distribution flow of clear priorities, cumshot, ago type the old or more near-term use.

- Classified according to the group, area, barcode, that the sign is clear.

ISO to note:

- ISO 9001 requirements management, information storage, clear, easy to access.

- ISO 22000 requires the food to ensure storage conditions, strict.

Perspective accounting: The right sort of help categorize assets, raw materials, precise, from which properly reflect the value of inventory under each account.

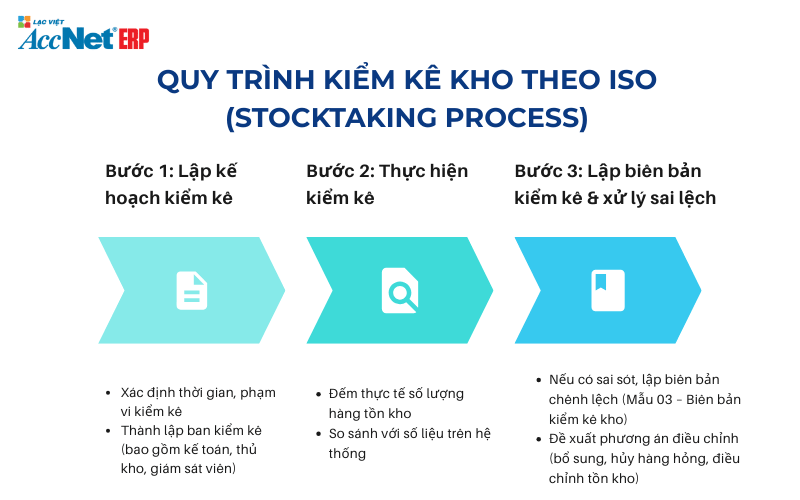

Step 3. Inventory control, inventory periodically in process inventory management according to ISO

A strong point of the ISO is required to control continuously, periodically, to avoid deflection, inventory, internal fraud.

The frequency of inventory recommendations: Quarterly or every 6 months, with record inventory with collated bookkeeping. Form ISO standards includes:

- Stock inventory

- Record gap

- Report adjust inventory value

Benefits of accounting:

- Increased reliability of financial data

- Ensure the right data to prepare financial reports under circular no. 200/2014/TT-BTC

Step 4. Export warehouse in accordance with standards

Operation storehouse is where easy to occur losses or errors if there is no clear process.

ISO standard requirements:

- Export warehouse to request internal or stock sale, with the signature level approval.

- Each are recorded number – item code – purpose use.

Connect with accountants warehouse:

- Auto, student, entry-reduction of inventory recorded the cost corresponding (for example: the Cost of unfinished production cost of sales).

- Ensure synchronized with system sales, manufacturing, if available.

Step 5. Data management – inventory report according to ISO

Standardized data: ISO request any information storage – recorded – transmission must have a unified format, can check access.

Features needed:

- Warehouse management software can integrate with accounting software (ERP or accounting left).

- Allows automatic reporting: inventory, end of period, rotation of inventory arbitrage inventory.

The greatest benefit: Accounting can retrieve data inventory at any time to service, financial analysis, internal audit or up tax reporting.

3. Benefits when applied to process warehouse management according to ISO into inventory accounting

Data transparency, reduce risk accounting

- There is a standard process helps accounted for right – enough – timely in the account warehouse.

- Minimize the lack of voucher books is the wrong number, or to adjust the accounting end of the period.

Enhance operational efficiency, financial reporting

- Save 20-30% of the time inventory, collated data.

- Reduce costs incurred due to errors in inventory or recorded input – output – inventory.

Create a platform to connect with ERP software/accounting overall

- ISO requires transparent system, from which facilitate the data integration between inventory and accounting.

- Process warehouse management according to ISO support reporting, internal administration (the price of capital, rotation, inventory, efficient use of raw materials).

Read more:

- Application RFID in warehouse management help reduce the loss of inventory

- Inventory management with QR Code giúp tự động hóa quy trình nhập xuất

- Tài khoản hàng tồn kho và cách hạch toán trong doanh nghiệp

4. Compare effective inventory management with and without ISO process

One of the most compelling for businesses to see the actual value of ISO is visually compare before – after applying the process.

| Criteria | Not according to ISO | According to the ISO process |

| Errors import – export | Often, difficult to control | Markedly reduced thanks to a form standard |

| Status loss of goods | High | Can control & access |

| Sync with accounting | Discrete input manually | Automatic, instantaneous link |

| Speed inventory | Slowly, craft | Shorten 40-60% of the time |

| Financial reporting | Or is the difference inventory | Data consistency, reliability |

| Reliability when audit | Easy excluded costs are not clear | Audited easy, vouchers full |

| Optimal rotation of inventory | Slow, high cost | Flexible, which saves inventory |

The numbers, the results showed that application process inventory management according to ISO is a profitable investments long-term business help tightly controlled warehouse operation – accounting, reduce losses, optimize cash flow, ready to audit at any time.

5. How to implement processes, inventory management according to ISO for small and medium enterprises

Not just for large corporations, ISO absolutely can apply in small and medium enterprises (SME) if you know the approaches at each stage:

Step 1. Assessment inventory management current

- Listed activities exist: receiving, storage, inventory, export warehouse

- Noted weaknesses: loss, lack of data, delay

Step 2. Select the ISO fit

- ISO 9001 is a priority, popular, best suited to standardized warehouse management system – accounting.

- If activities in the field of food, pharmaceutical, add ISO 22000.

Step 3. Building material, process, form

- Design, diagram, workflow, from import – export – inventory – report.

- Standardized form: Votes for import, export, inventory adjustments, inventory, window track.

Step 4. Training personnel task assignments

- Personnel inventory to understand the role, the process, how recorded data.

- The accounting department should coordinate to accurately reflect on the books.

Step 5. Software application support ISO

- Priority software with integrated accounting – inventory – sales order to optimally operate.

6. Hint warehouse management software that supports ISO

A good software will play the role of “brain coordination” the entire process of inventory management according to the ISO for the business.

The software supports ISO:

- There are forms import – export – inventory-ISO

- Automatic data link between parts warehouse - accounting

- Support monitor rotation of inventory, inventory periodically, the price of capital

- Integrated analysis report: inventory of safety, the slow rotation, the rate of attrition

Learn more:

- Kiểm kê hàng tồn kho định kỳ giúp phát hiện sai lệch kịp thời

- Admin inventory in logistics giúp tối ưu chuỗi cung ứng

- Principles ABC in warehouse management giúp tối ưu tồn kho

Solution hints: AccNet Inventory - warehouse management software, specialized, can be integrated with AccNet Cloud to synchronize accounting data. Support system:

- Track inventory by lot, shelf location

- Process management export – import – inventory clear

- Set up inventory report, inventory reconciliations, ledger automatically

- In addition to AccNet Inventory then FAST Inventory, Bravo ERP, MISA SME is also the solution can integrate to standardized accounting data warehouse

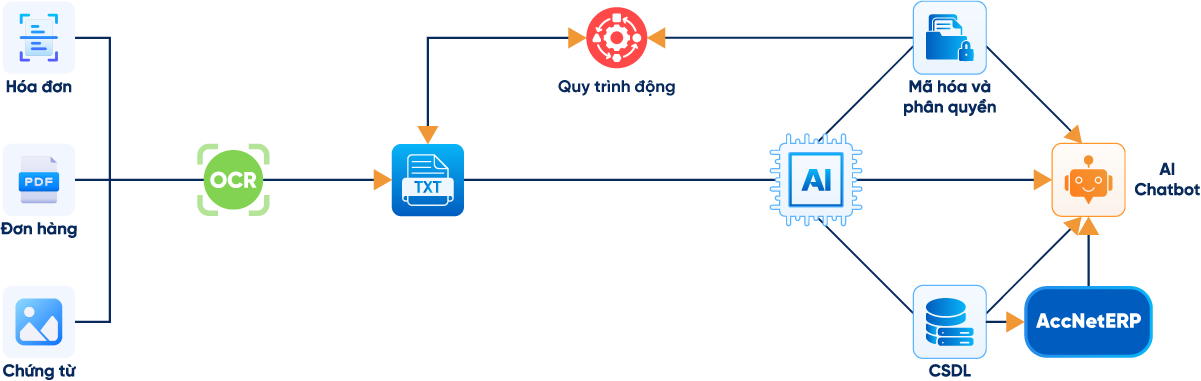

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

The application process warehouse management according to ISO no longer is choice, which is the inevitable trend in the development of sustainable business. Here is the solution to help businesses:

- Enhance operational efficiency repository

- Ensure accurate accounting data inventory

- Ready audit – financial reporting transparency

- Optimal cost, shorten the rotation of capital to support strategic decisions

Don't let the warehouse is “bottlenecks” in the operation of accounting. Let's start standardized today with process inventory management according to ISO, accounting software integration, to each of the numbers on the financial statements have practical value, strategy.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: