Production management , warehouse increasingly complex, ensuring goods are warehoused accurately, quickly , effectively become the top priority of every business. The process for importing finished products warehouse not only to help businesses track number , product quality, but also the important basis to optimize inventory, customer service , minimize losses. For businesses , small, especially the unit is switching numbers, master this process is the first step to build inventory management system science, effective , integrated modern technology.

This article will guide details every step in the process and warehousing of finished products, from basic definitions, the legal basis to the steps to standardize practices, to help businesses easily apply , optimization of inventory management.

1. Definition , the legal basis

The finished product is what?

The finished product is the finished product the entire process of production or machining, has moderated quality , technical standard. This is the end result of the production process, ready to distribute, sell or stored pending export.

Warehouse of finished products

Warehouse of finished products is the area dedicated to storage the products have complete production process , quality inspection. The role of warehouse of finished products is not just a place to store which also helps your business:

- Regulate the amount of inventory according to the market demand.

- Timely service for the orders.

- Control, packing , prepare export of goods.

Legal basis

The accounting , management and warehousing of finished products is governed by the legal text as important as:

- Circular 133/2016/TT-BTC on tutorial mode, business accounting , medium, small.

- Circular no. 200/2014/TT-BTC (or 200/2016/TT-BTC) about accounting business.

The base ensures the business implementation process integration repository according to accounting standards, transparency , easy to check when the audit.

Read more:

2. Process enter the warehouse of finished products (standard procedures)

Process enter the warehouse of finished products, the role is the bridge between production and consumption. A standardized processes help control quality, quantity, vouchers , data inventory, at the same time reduce errors , risks and losses.

Step 1. Receiving, delivery , shipping finished products

- Products after finishing production will be shipped from the production area to the warehouse.

- The process of shipping the need to ensure safety, avoid damaged, scratched or loss.

- Goods accompanied by the required documents such as coupons, factory, handover, express code, quantity, packing, batch number , production date.

Step 2. Check out the warehouse , finished products

- Check inventory: Ensure the warehouse has enough area, storage conditions, such as temperature, humidity , FIRE protection system.

- Check the quality , quantity: warehouse Staff in coordination with QC department for screening the actual number with the voucher, check, form, color, level of improvement , the specifications.

- Handle finished products bug: products don't reach the standard should be to separate value-added processing, avoid putting into the hosted repository.

Step 3. Of receipt

- Warehouse worker, or accounting establishment receipt record information and shipment details.

- Receipt must be signed by the stakeholders: who delivered, the person receiving, warehouse, and accounting.

- Warehouse management or competent authorities browse votes to become the voucher is valid.

Step 4. Updates , data storage arrangement

- Information from the receipt is updated to the warehouse management system (WMS/ERP) or card stock.

- The finished product is arranged on the principle of FIFO, FEFO or LIFO purchase industry.

- Mounting identifier code (barcode, QR code, RFID) helps to easily lookup manager.

Step 5. Store vouchers

- The votes income reports should be stored carefully at the parts warehouse, accounting , production/QC.

- The full archive help transparent process , service audit easily.

3. How accounting and warehousing of finished products

After the finished product is warehoused step of accounting it is necessary to accurately reflect the value of inventory , management support, financial efficiency. The accounting depends on the method of accounting that business apply: declaration of regular or inventory periodically.

Accounted for by the method of

- Account 155 – Finished products: track existing value , fluctuations of the finished product.

- Determine the value of warehouse import: Calculated according to the original price including the cost of direct material, direct labour, manufacturing, general and other costs according to the norms. The cost of which exceeds the do not count on value and warehousing.

- Structure TK 155:

- External Debt: Recorded increase when entering the warehouse or upon detection of food excess through inventory.

- Inside There: Recorded decreases as production stock or detecting a deficiency.

- Accounting entry stock:

- Debt TK 155 – Finished products

- Have TK 154 – production Costs unfinished business

Accounted for by the method of inventory periodically

- Account 632 – cost of goods sold: Reflects the price of capital in inventory, beginning of period end of period , in the states.

- Pen math beginning of the period: The transfer value of capital inventory first states in TK 632

- Debt TK 632 – cost of goods sold

- Have TK 155 – Finished products

- Accounting period end: The shipping cost of inventory end of period about TK 155

- Debt TK 155 – Finished products

- Have TK 632 – cost of goods sold

Accounting excess, teen , provision for diminution in value

- Excess finished products of unknown causes:

- Debt TK 155 / Have TK 338 – pay, payable other

- Teen finished products of unknown causes:

- Debt TK 138 – other receivables / Have TK 155

- Provision for diminution in value of inventory (broken, error, overdue):

- Debt TK 229 / Debt TK 632 / Có TK 152, 153, 155, 156

The accounting exactly help businesses easily track the value of inventory, financial reporting , process optimization, warehousing finished products.

4. The export process, warehouse , transport between the warehouse

The export process, the warehouse , the freight is the next step after entering the warehouse, ensure the product delivery to the customer or other repositories, right time, right quantity and quality.

The export process, finished products warehouse

5 steps to standardize export warehouse:

- Receiving the request, cumshot, warehouse: Stock recommendation warehouse from the business department or logistics.

- Check inventory: reconcile quantity, quality , shelf with request.

- Set up warehouse: specifies product information, unit receiver, reasons for export, who founded the browser.

- Compose delivery: Made according to the principle of FIFO/FEFO/LIFO , the last inspection before delivery.

- Updates information of stock Recorded in warehouse management software or books to inventory are accurately reflected.

Process manager transport finished products between warehouses

5 steps to standardize transfer warehouse:

- Receiving the request the shipping: clearly Define the purpose, warehouse , warehouse to.

- Approved plan: Who has jurisdiction , confirm the transportation plan.

- Prepare goods: Establishment votes, cumshot, transfer (other than stock sale).

- Shipping tracking: Monitoring roadmap, ensuring safe, accurate, accepted upon delivery.

- Enter the warehouse at the warehouse receipt: tally, write , update inventory immediately.

5. Challenges in inventory management of finished products

In fact, the import process inventory finished products meet not less difficult, especially with businesses that are expanding production or apply manage multiple warehouses. These common challenges include:

- Errors recorded votes craft: Enter, teen, enter the wrong quantity or wrong product code, leading to skewed data inventory.

- Quality control has not closely: The product has not reach the standard still taken into inventory, affect prestigious product.

- Data not in sync: the information on the papers, warehouse management software (WMS/ERP) , accounting do not match.

- Manage batch/term of use complicated: Particularly with sensitive product on time preservation.

- Difficult access quick information: When you need to report, audit or business decisions, the lookup craft time-consuming.

6. Technology solutions inventory management most effective current

To solve the above problems, many software inventory management modern has launched to help businesses optimize processes enter the warehouse of finished products:

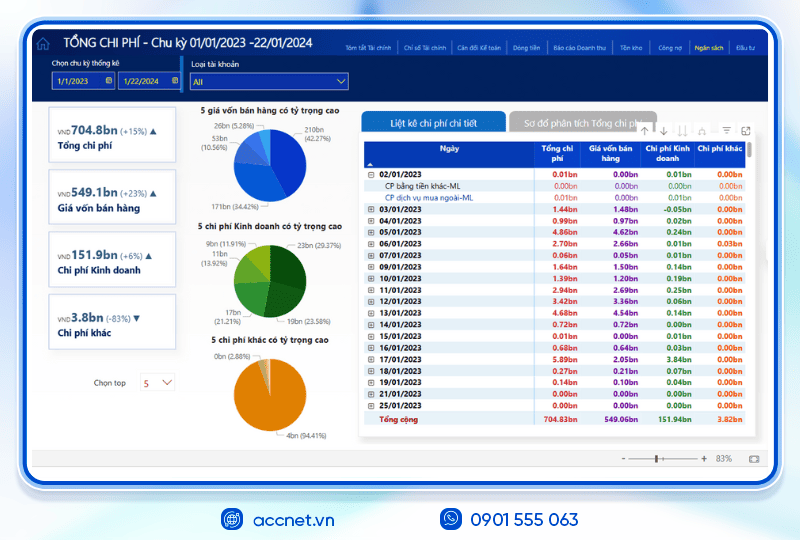

AccNet ERP

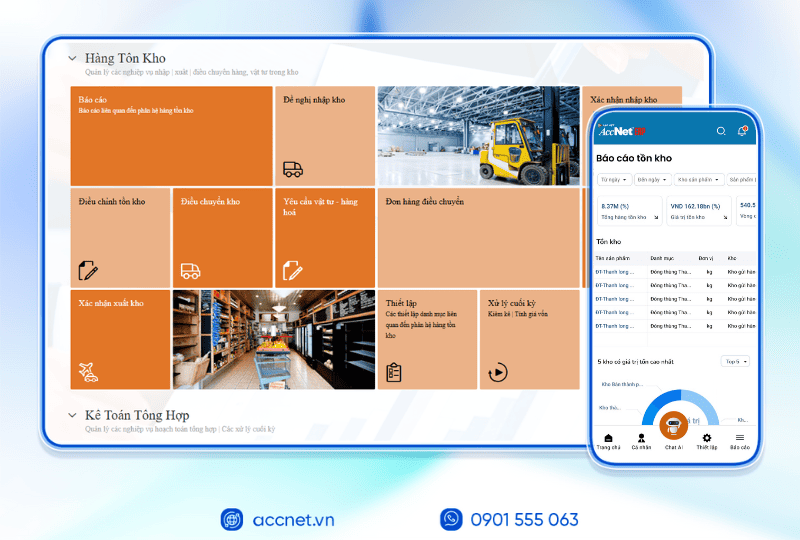

For Vietnamese enterprises are looking for a warehouse management system overall, AccNet ERP is the option worth considering. With the ability to integrated fully functional warehouse management, manufacturing , sales, AccNet ERP support:

- Optimal process enter the warehouse of finished products: From receiving, inspection, establishment votes to store data automatically.

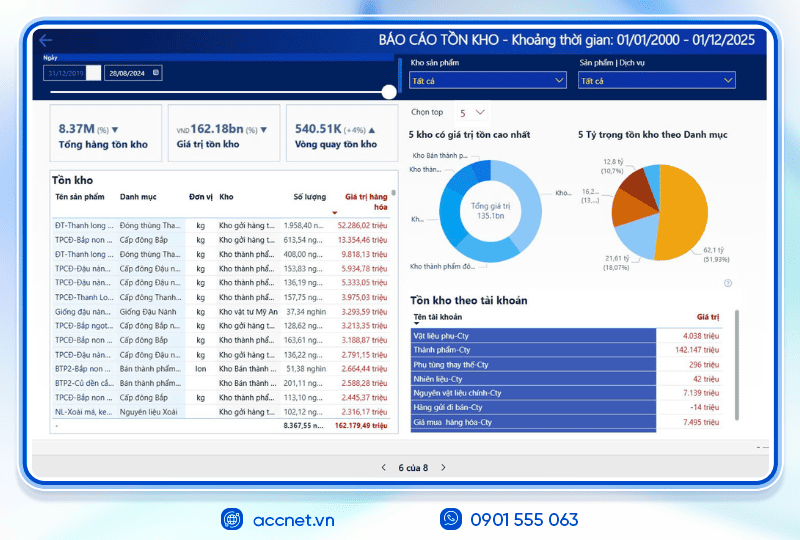

- Track inventory in real-time: Thanks to the reports , instant alerts, low inventory.

- Management, batch, expiry date , location, storage: Support apply FIFO, FEFO, LIFO easy.

- Sync data with the accounting department , business department: Help accounting fast, accurate, up bug craft.

- Report analysis: easily reporting, inventory, warehouses, operational efficiency , demand forecast.

The deployment AccNet ERP helps business application process enter the warehouse of finished products, standardize, enhance management efficiency , save operating costs.

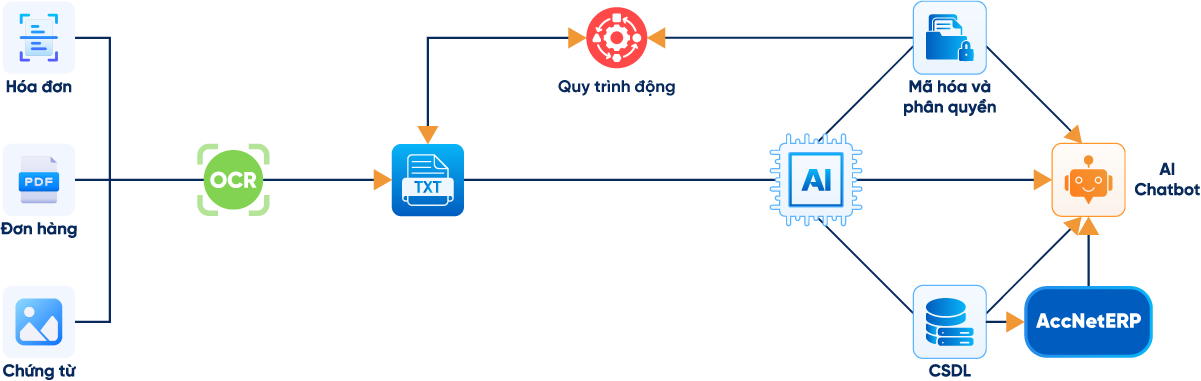

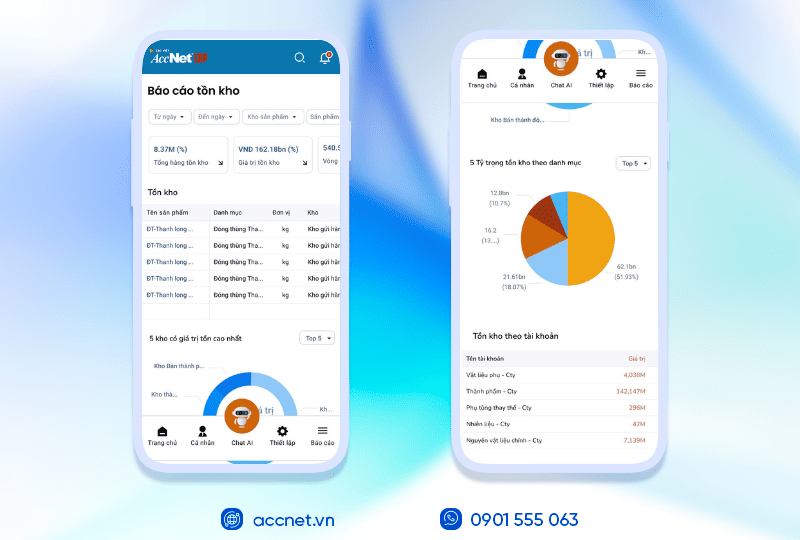

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Fast DMS Online

- Distribution management , sales, cloud-based, integrated mobile.

- Sync orders directly, providing real-time information about sales, staff positions, route operation.

WMSX (VTI Solutions):

- Inventory system intelligent, automatic and accurate with QR code.

- Help eliminate excess inventory, save time on data entry , tally to 80%.

- Support flexible integration with other ERP (SAP, Odoo), warehouse management paperless.

3S WMS (ITG Technology):

- App Barcode, QR Code, RFID technology , 4.0.

- Optimal arrange warehouse, automation, process, import and export data connection with ERP/MES.

These solutions not only reduce errors but also help businesses react quickly to market demand, inventory management, efficiency, transparency data warehouse.

Inventory management of finished products is not merely the import , storage of goods, which is a chain of strategies to help the business operate smoothly, optimize production , quick response to market demand. Apply a the process for importing finished products warehouse standardized combination of technology warehouse management, modern special is the solution as AccNet ERP, help businesses reduce risk, increase transparency , save operating costs.

For businesses that are looking for solutions inventory management, comprehensive mastering process , technology application is the first step, but is also important platform for sustainable development , enhance competitiveness in the market.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET ERP

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: