The maintenance of stable resources, minimize costs , optimize the operation to become the first priority of the business. Admin inventory in logistics play a decisive role in ensuring goods are always available on demand, at the same time limiting waste , risks arise. Businesses not only need to manage the amount of which must also be optimized storage location, time, rotation, efficient operation of warehousing. A strategy for inventory management, it helps businesses improve customer experience, increase speed of delivery , providing accurate data to serve the decision.

1. The concept of administration inventory in logistics

Concept

Admin inventory in logistics is the process of monitoring, control , optimization, goods from the moment of entering the warehouse to the warehouse. The goal is balance between demand , supply, while reducing the cost of storage and increase the efficient use of space. The business casual planning, import, storage, distribution, at the same time check the status of the product to avoid shortages or inventory too much.

In the environment of logistics, there are differences between warehouses , warehouse:

- Warehouse (Warehouse): warehouse standards, primarily storage and preservation of goods for small businesses , medium-sized. Inventory focus on the quality control , managing the correct number.

- Warehouse (Warehouse Yard): large area outdoors to the bulky goods or means. Warehouse management more complex layout requires science to maximize productivity and reduce operating costs.

Classification and inventory management goods

Business casual classification of inventory based on the nature of the goods to deploy management inventory in logistics efficiency:

- The storage of raw materials , components: includes the raw materials , semi-finished products. The strict management ensure the production process is not interrupted.

- Finished product warehouse: storage finished product, ready to put on the market. These items often have high value , requiring conservation measures stringent.

- Warehouse packing materials: included packaging, carton, pallet... These materials need to be managed to be always ready to serve the packaging products.

Read more:

Importance & benefits

Admin inventory in logistics not only directly affect the operational efficiency warehouses, but also impacts the entire supply chain. A system of inventory management science brings many practical benefits:

- Ensure continuous supply chain: Help balance supply , demand, avoid shortages or inventory excessive.

- Reduce operating costs: inventory control optimization helps to reduce storage costs, administration , transportation.

- Optimal space warehouse: scientific Arrangement helps to save the cost of renting warehouse , maintenance, at the same time improve the effective use area.

- Increase the ability to react to market: the System of flexible management to help businesses quickly adjust the source of goods before fluctuating demand.

- Detect , mitigate risk: strict control to help prevent damage, loss or errors in the process of storage.

- Advanced product quality: Ensure the goods are preserved in good condition, maintain the quality before export warehouse.

- Speed delivery: Support the process of processing orders quickly, enhance the customer experience.

- Decision support precision: Data from warehouse management to provide valuable information for production planning , distribution strategies.

2. The works mainly in warehouse management, logistics

Warehousing is the central operation of the supply chain. To maximize efficiency, businesses need to perform the activity management inventory items:

- Consignee (Receiving): When the goods arrive at the warehouse, the first step is to check the number, quality, accurately recorded into the system. This will help early detection of damaged goods, missing or wrong categories, and create data for the next step in management inventory in logistics.

- Take goods (Put-away): goods after receive will be transported to storage area suitable. The choice of location storage and reasonable, not only save time when goods but also optimal storage space.

- Store inventory (Inventory Storage): goods are sorted by groups and categories, size, value or frequency of use. Streamlined help reduce the search time, at the same time to limit damage or loss.

- Order picking (Picking): warehouse worker choose products according to orders. A layout system science help speed up the process of picking, reduce errors , enhance the precision of every step.

- Packing (Packing): goods are wrapped securely, anti-shock, shatter, attach the shipping label. Packing process standardization help protect products , to create convenient for transporting.

- Carriage (Shipping): goods are coordinating logistics with the carriage unit. Information tracking is updated automatically for the clients, to ensure timely delivery , transparent.

- Subdivision/institutional repository (Slotting): warehouse layout according to the region or frequency input help optimize space, reduce the time of operation , reducing errors when get the goods.

- Report (Reporting): periodic reports about inventory, import, damaged, performance warehouse is an important basis for decision-making, strategy , process improvement manager.

3. Process management inventory in Logistics

To deploy management inventory in logistics efficiency, enterprises need to build a process overall, from planning to control and report:

Step 1. Planning warehouse (Warehouse Planning)

Plan stock is the step platform, including:

- Specify the repository location convenient for the reception and distribution.

- Divided storage area clear.

- Forecast amount of goods in and out to layout the space, reasonable, reduce congestion , and losses.

Read more:

Step 2. Warehousing , planning and warehousing

Businesses need to ensure goods entering the correct type, quality, quantity , time. Check carefully labeled details help reduce your risk of confusion , damaged. This data is also the basis for the report, import , track inventory.

Step 3. Storage goods (Storage)

The sort of scientific goods decided to operating speed , the accuracy of the repository:

- Taxonomy: Based on the type, size, value.

- Zoning: Split archives into separate partition for each type of goods.

- ABC: Classified according to level of importance, often taking place in accessible location.

- Storage multi-tier: Take advantage of vertical space to optimum area.

Step 4. Prepare the goods , planned export warehouse

Before export warehouse, goods should be checked on quality, quantity , status. Plan export warehouse help:

- Packing standardized.

- Inventory match the amount with the system.

- Ensure the delivery on time , location.

Step 5. Packing , export warehouse

Goods are packed securely, arrange optimized to save shipping costs. Then, the product is recorded export warehouse in system management, reduce inventory, respectively.

Step 6. Receipt of goods is paid (Finished goods)

When there are returns, the business needs classification: reuse, recycling, destruction or pay suppliers. This process consists of 7 steps, from receiving, inspection, classification to analyze the causes to reduce the risk to repeat.

Step 7. Check items (inventory periodically)

Regular inventory helps to detect flaws, damage , adjust inventory in a timely manner. The common methods:

- Inventory of the whole: the Whole repository is checked.

- Inventory cycle: Split archives into parts, checking at each cycle in order to not interrupt the operation.

Step 8. Statistics and reports

The report provides overview of inventory: inventory, import, damaged goods, performance, cost difference compared to inventory levels optimal. This is an important basis for business decisions strategy , optimal operation.

4. The method of management effective inventory

To achieve optimum efficiency in the management of inventory in logistics, business need to apply the scientific method combined with modern technology.

Handle inventory in the system

- FIFO (First-In-First-Out): Preferred stock the products enter first. This method is especially suitable for goods have limited use as short as food, cosmetics, consumer.

- LIFO (Last-In-First-Out): Export these products enter the following apply to materials inventory as long as building material, helps to balance the cost , the price of capital.

- FEFO (First Expired-First-Out): the product is about to expire ago to ensure quality, reduce waste , and inventory obsolescence.

Learn more:

Organization , layout warehousing

- Divided storage area: goods placed on the nature, frequency, import , importance level. The export goods should regularly near the entrance door.

- Sort by SKU (Stock Keeping Unit): Set the code separately for each item, convenient for inventory, access , data analysis.

- Plan warehouse layout: layout science to help optimize space, with easy access to the selling items, reducing the time picking.

- Location bins (Bin location) , labeling: Each item has its own position, combined barcode, help manipulate, accurate , fast.

Standardized processes , training

- Unified standards with partners: Identify standard packing, size, number, information on the label , on-time delivery.

- Management, strict process: Compliance with the entry process inventory, warehousing, production, warehouse, inventory and distribution to reduce errors and optimize cost.

- Staff training: instructions on how to use barcode scanner, complete orders, operate a warehouse efficiency.

Technology application software

In the digital era, management of inventory in the logistics can not lack of support of technology. The modern solution to help businesses tightly controlled, reducing , increasing efficiency:

- Barcode management system inventory information: Scan the SKU, track rotation , inventory, news time, reduce errors and human.

- ERP software , warehouse management: Help record all activities of import and export management position supplies, shipment term use , providing analysis reports.

- Intelligent reports: The software supports to export reports, inventory, ABC analysis, trend, import , performance warehouse.

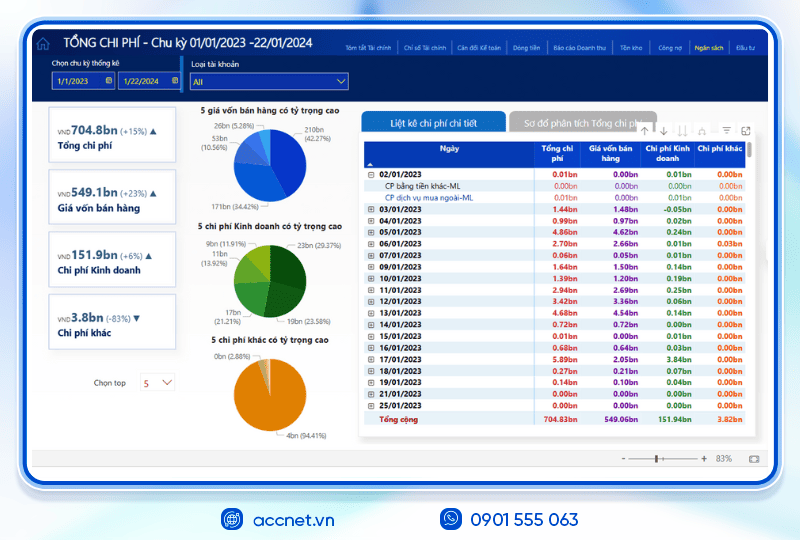

5. Solution inventory management AccNet ERP

For businesses that are looking for the solution of chemical management inventory in logistics, AccNet ERP is comprehensive selection:

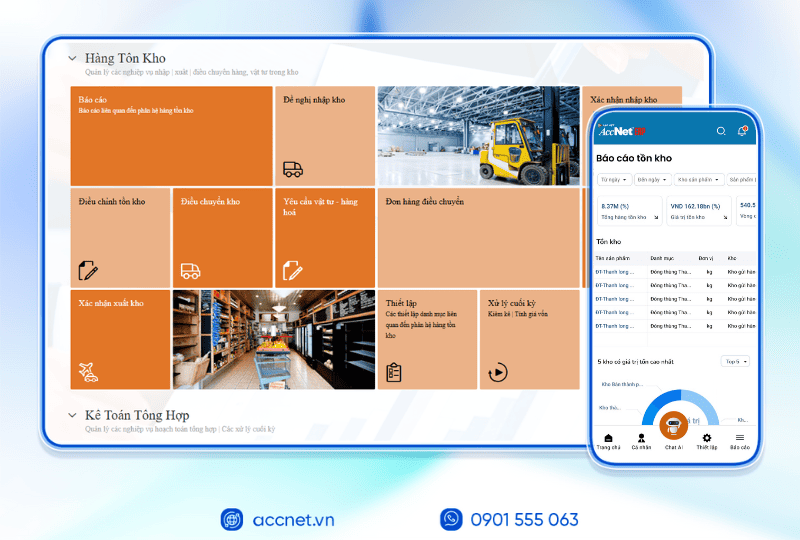

- Integrate the whole process: From warehousing, storage, storehouse, to inventory and report.

- Cargo tracking lot, expiry date , exact location to Help businesses reduce losses, optimize space , speed up order processing.

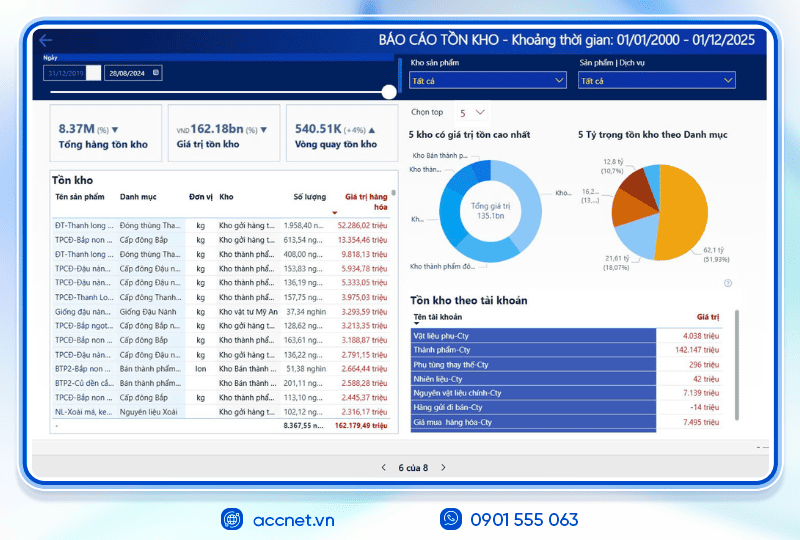

- Reporting, intelligent analysis: Provide data on freight movement, inventory optimization, operating costs.

- Compatible with barcode , the scanner device: advanced efficient operation, reducing error , crafts, increased productivity.

- Decision support: real-time Data helps to plan production, distribution , adjust business strategies quickly.

With AccNet ERP, businesses can deploy strategy, inventory management, modern, optimize cost , enhance the ability to serve customers. System help operator warehouse efficiency, ensure the goods always-ready, high quality , timely, satisfy all the market's volatility.

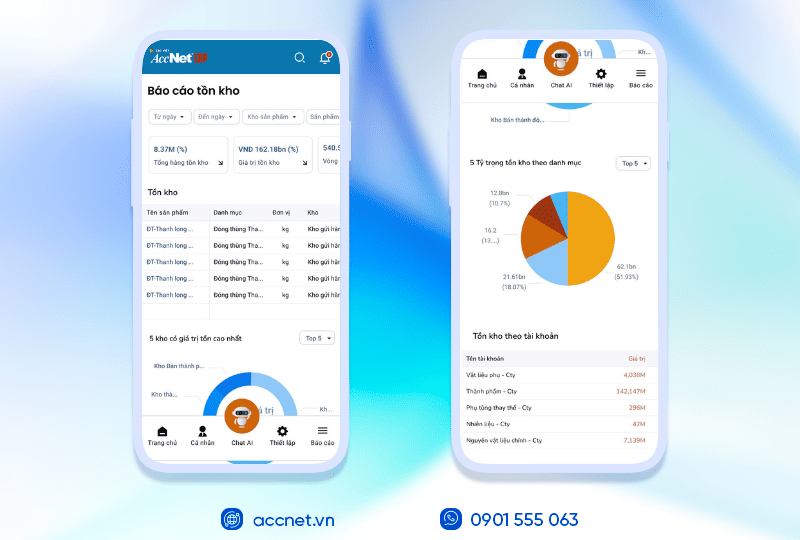

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

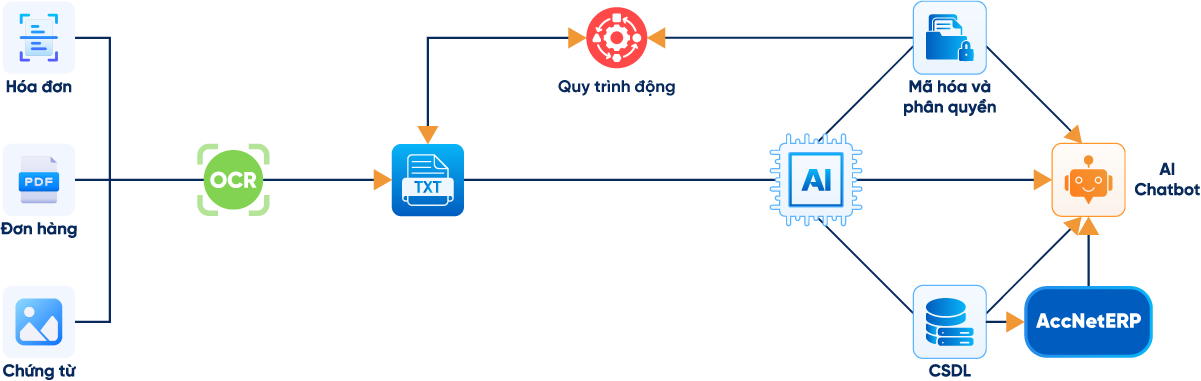

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Admin inventory in logistics no longer is the task that become a core strategy of the business. The applied methods of scientific management, combined standardized processes , technology applications, such as AccNet ERP help optimize costs, increase operating speed, improving the quality of products , improve the customer experience. Any business implementing effective inventory management will have competitive advantages, sustainability, risk reduction , ready to meet the market demand flexibly.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET ERP

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: