The inventory control is not merely the story of the operation that has become a part financial strategy business. Especially with those businesses that are entering the implementation phase or improved accounting system inventory, then manage the number of goods is a core element helps to ensure accuracy, transparency, cost control efficiency.

According to a report from McKinsey (2023), the business successful deployment solution to manage the number of goods modern can be reduced by up to 40% loss of stock, an increase of 30% accuracy in financial reporting. This indicates the important role of the construction of a control system of quality goods basically – not only to accurate inventory but also to support governance decisions at the right time.

This article will help you – the house manager, chief accountant, chief operating officer – understood “how to manage the quantity of goods” from definition to practical deployment, at the same time hint tool, the most effective method today.

1. Why manage the number of goods is a key factor in accounting stock?

Direct impact on operating costs, cash flow

A business can't manage good cash flow if not, control the exact amount of inventory. Inventory virtual teen rows as needed, the excess when not need... are causing financial waste, misappropriation of funds, seriously affect liquidity.

Affect the accuracy of financial statements

Cargo is a part of short-term assets. If not, get a number, value of inventory, the business can report false profits, influence, transparency, ability to raise capital.

How to manage the number of goods Is the basis for decision-making buy – sell – production

Accountant role of bridge between production department, business, finance. When there is data in the number of accurate business can build the level of inventory optimization, thereby making the decision to purchase, manufacture, or freight movement reasonable.

Minimize the risk of errors, fraud, loss

The difference between the actual figures, the book is one of the leading causes risk of fraud or loss of goods especially in industries such as retail, manufacturing, food – where the volume of transactions is very large.

Read more:

- Solutions cargo management smart for business modern

- Cargo management inventory correct method helps reduce the cost of storage

- File inventory management with Excel free for small business

2. The method to manage the number of goods popular today

When done how to manage the number of goods, the business can choose from several methods depending on the scale, industry, level of investment in technology. Here are the popular methods are being applied in practice.

Method (book, Excel)

- Description: Recorded input – output – inventory by hand or Excel file simple.

- Advantages: low Cost, easy to deploy with small business.

- Restrictions:

- Easy to errors due to input manually.

- Not able to track real time.

- Hard to control when the scale of goods, the number of transactions increases.

- Conclusion: in accordance with small business, but should not be applied long-term due to the risk of deviation.

Methods of making the goods code batch code, batch

- Description: Assign a separate code for each batch of products to help access management, batch import/export.

- Benefits:

- Very suitable for food industry, pharmaceutical manufacturing – where goods need to be classified according to the expiration date or origin.

- Easy recovery shipment errors when needed.

- Requirements: Need a software system or form support encryption.

How to manage the number of goods by accounting software dedicated warehouse

- Highlights:

- Auto tracking, real-time input – output – inventory.

- Connect the device to scan barcodes, QR codes, RFID to ensure accuracy.

- Automatically generate coupons import/export, windows, inventory reports, fluctuations in inventory.

- Benefits for accounting:

- Discount 70-90% of the volume of work.

- Collate data between fact, accounting is more accurate.

- Suggested software: AccNet InventoryBravo , MISA, FAST, Odoo ERP...

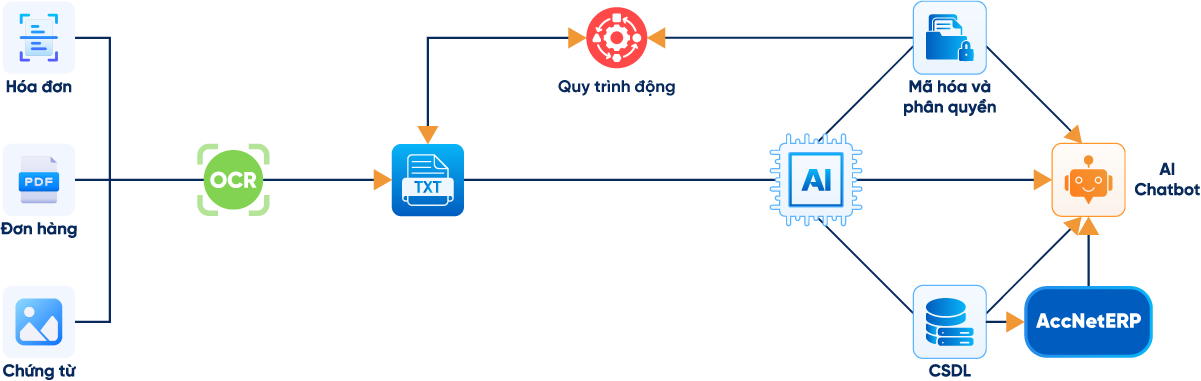

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI” Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp: AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn. ✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát” ✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI ĐĂNG KÝ NHẬN DEMO NGAY Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng ✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp ✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

How to manage the quantity of goods according to FIFO method, LIFO, JIT, ABC

| Method | Description | Common applications |

| FIFO (First In – First Out) | Imports ago be ago | The food industry, cosmetics |

| LIFO (Last In – First Out) | Orders enter the following are prerendered | The construction industry, raw materials |

| JIT (Just In Time) | The row came at the right time to use | Business lean manufacturing |

| ABC | Classification of goods under the value and level of consumption (A – B – C) | Portfolio management diversity |

Choosing the right method should be based on the business model, scale warehouse, the ability to invest in technology.

3. The implementation steps how to manage the quantity of goods effectively in business

To building management system, the number of goods durable, easy to operate, the business should be deployed in 5 normalization steps below:

Step 1: standardize the list of goods

- Create lists of goods under unique code (SKU), with information, description, unit, section, shelf, unit price.

- Apply the inventory levels at a minimum for each code.

- Benefits: Helps accounting easy lookup, to avoid confusion, support alerts, inventory unusual.

Practical example: Business electronics manufacturing standardized 500 code components, help shorten the duration of inventory from 3 days to 6 hours.

Step 2: build process import – export – clear inventory

- Clearly define the responsibility of each department: purchasing, inventory, accounting, manufacturing.

- Standardized form, receipt, stock, stock inventory.

- Integrated process to check the quality of the goods before recorded into the treasury in the administration of the quantity of goods.

Note: Set 2 approval step with the higher value to avoid false, misleading or fraudulent.

Step 3: application software, inventory accounting or ERP software

- Priority software options are:

- Inventory alert for pass/teen norm.

- Integrated with sales, production, accounting and finance.

- Allows traceability by lot number, expiry date, delivery note.

- Positive impact:

- Minimize errors manually.

- Speed up order processing, export – import.

- Decision support inventory flexibility in time.

Step 4: decentralization, threading responsibility by location

- Decentralized access software according to the role: the warehouse, accounting, internal controls, leadership.

- Clearly define responsibilities, KPI for each department related to goods.

- Benefits of this step in how to manage the number of goods: Increase transparency, prosecution clear upon the occurrence of errors.

Step 5: set control reports periodically (weekly, monthly, quarterly)

- The report type should implement:

- Report import – export – survival according to code.

- Reporting of conservation of slow rotation.

- Reports collated fact – book – software.

- Suggestions: Use dashboard actions, chart inventory over time to track trends.

- Suggestions: setting dynamic reporting (dashboard) is directly related to the leadership track instant.

4. Common mistakes when performing the way to manage the number of goods

Although deployed inventory accounting, many businesses still have the common error led to deviations of data, loss of goods, congestion cash flow. Here are the common errors, how to fix:

Not timely updating of the fluctuations in stock

- Bugs: Record the receipt of goods import/export delays that accounting data do not match with reality.

- Consequences: Leads to the decision to buy more goods, while stock still, or not enough inventory to meet orders.

- How to fix: Use accounting software inventory features real-time updates, connect with the system of sales or production.

Confused, commodity code unit of measure

- Bugs: the product of the same name, but different specification or packing (kg – carton – box) is recorded general.

- How to fix: Standardized code SKU, a clear distinction between unit root calculator, unit conversion.

Not collated periodically between the real – book – software

- Consequences: Not detected in time difference, causing the wrong number of cumulative over time.

- How to fix: calendar set inventory periodic reports collated automatically.

Input errors crafts

- Risk: wrong number, wrong item, the wrong warehouse.

- Solution: Use the device to scan barcodes, input, through the software can auto hints.

Process in how to manage the quantity of the goods has not decentralized clear

- Consequences: Anyone can edit data, difficult to control fraud or error.

- Recommendation: set the access rights division, recorded diary manipulation (log).

5. Software inventory accounting: The ultimate tool to manage the number of goods

In the context of the number of goods is increasingly diverse, transaction speed, fast, business can't control inventory effectively if based only on method. Accounting software stock modern is answer key comprehensive.

Outstanding benefits:

- Instantaneous monitoring the entire import – export – inventory item code, the code repository branch.

- Automation reports: inventory daily, slow-moving, alert nearest expiration.

- Connection system sales – purchase – production data throughout.

- Up to 80% of the volume of accounting work warehouse, advanced accuracy.

Criteria for selecting the right software:

- Features inventory alert pass/teen norm.

- Integrated management batch – barcode – term use.

- Easy to use interface, support multiple users.

- Scalable to scale the business.

According to the survey of Vietnam Report (2024), 65% of business after implementing accounting software inventory instead manage the number of goods have dropped over 30% of the cost of inventory management, increase 50% accuracy of inventory compared to the previous period.

6. New trends in management of quality of goods

Digital technology is changing the way business approaches management of goods. Here are the trends businesses need to capture:

Automation, AI, IoT, RFID

- Mounted sensor automatic measurement of inventory.

- AI trend analysis, inventory – consumption to hint at plans to enter the restaurant.

Management throughout the supply chain

- Integrated accounting system inventory with financial software – purchase order – CRM – production.

- Create a data flow consistency, reduce risk, deviations between the parts.

The report, smart alert

- Warning of inventory exceeds the maximum level.

- The proposed automated order when inventory hits a minimum threshold.

How to manage the quantity of goods not merely work to operate – it is a part of strategic cost management, enterprise asset. Especially with businesses that are in the construction phase or digitize accounting system, inventory, understanding, implementing the right methods, processes, tools, inventory management will help:

- Reduce costs, reduce risks and losses.

- Increase financial transparency.

- Decisions operating correctly and timely.

For businesses that are in the transition period of, or construction of the inventory accounting system professional, the investment into the process to manage the number of goods not only is the solution operator, which is also profitable investments in the long term. So, today, let's:

- Revise the entire management process of goods current.

- Standardize the item code, the inventory levels.

- Implementing accounting software repository dedicated to automation, transparency, speed control.

If you need advice or experience testing software solutions manage the number of goods in-depth, please contact us today. The opportunity tightly controlled warehouse – optimal financial is in your hands.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: