According to a survey by Statista, more than 60% of enterprises have difficulty in managing inventory due to lack of clear process. If not built standardized processes, shipment will easily lead to errors, causing loss of property. So the export process, the repository is what? How to deploy standardized? Article below AccNet will help the business understand every step in the process.

1. Definition of the process of stock, what is?

The export process inventory is the set of steps taken to record the goods leave the warehouse to cater for:

- Production: Production of raw materials for the production process products.

- Sales: Export finished products for delivery to customers.

- Internal use: goods for the purpose of internal use by the business.

This process is recorded closely through vouchers as warehouse, updates on bookkeeping. Process shipment, it brings many benefits for business:

- 't happen losses or recorded deviations.

- Recorded in full figures, meet accounting standards in Vietnam (VAS).

- Reduce errors in accounting, minimize errors from human.

According to research by Gartner, the business application process export standard incorporates technology inventory management can be reduced to 30% of the cost of loss of goods, increase accuracy inventory up to 98%.

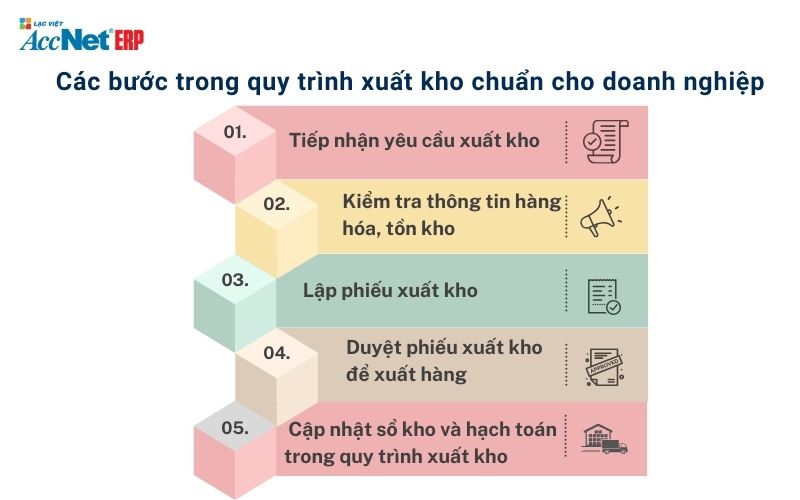

2. The steps in the process. the standard for business

Step 1: receiving the request export warehouse

The first step is receiving the information required stock from parts needs. This request is often made in the form of:

- Request stock from production department/business.

- Clearly define the purpose of stock for production; Export; Export internal use.

Read more:

Step 2: Check information, inventory

This step in the export process, warehouse to ensure the quantity of goods in stock to fully meet the requirements of stock

- Parts inventory check directly the number of rows in the warehouse.

- Compare data inventory on software/ledger with actual data.

- Establishment status report, notification to the relevant department.

Actual figures: 70% of businesses experiencing a false inventory when using the management method manually. Technology solutions Accnet ERP help improve the accuracy up to 95%.

Step 3: Set up warehouse

Warehouse user to confirm the goods from the warehouse. Content featured include:

- Code commodity name of goods

- The number of goods export warehouse

- Reason of stock (production, sales, internal)

- Consignee parts get

Warehouse need to comply with accounting standards under circular no. 200/2014/TT-BTC and circular 133/2016/TT-BTC.

Step 4: Browse warehouse to shipment

Process browser warehouse:

- The warehouse for the competent person (inventory management/supply on).

- Approved warehouse.

- Proceed shipment reality according to the number on the coupon.

Step 5: Update windows inventory and accounting in the process of stock

After shipment, accounting department, proceed to update the information on windows warehouse, execution of accounting. The account:

- Debt TK 621 (cost of raw materials directly) or TK 641/642.

- Have TK 152/155/156 (raw materials, finished products).

Illustrative examples accounting: Production of 1,000 kg of raw material for production

- Debt 621: 50.000.000

- There are 152: the 50,000,000

3. The common error in the export process, warehouse

3.1. Difference between book inventory and actual

- Data of import - export warehouse is not updated timely.

- Process inventory inaccuracy, non-recurring.

- Staff recorded the wrong number, code goods.

Read more: Cách tiếp nhận và lưu kho hàng hóa sau sản xuất đúng quy định

3.2. Incomplete vouchers export warehouse

- Vouchers not full makes business't enough legal basis to process when there are inspection and audit.

- Affect the financial reporting accuracy.

3.3. Error accounted for the wrong account

- Staff accountant confused when the designated account.

- The process of stock have not been standardized, clear.

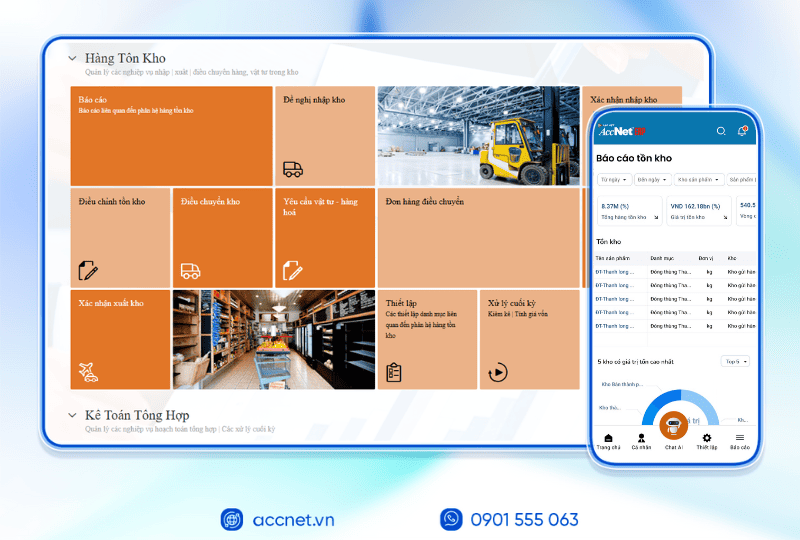

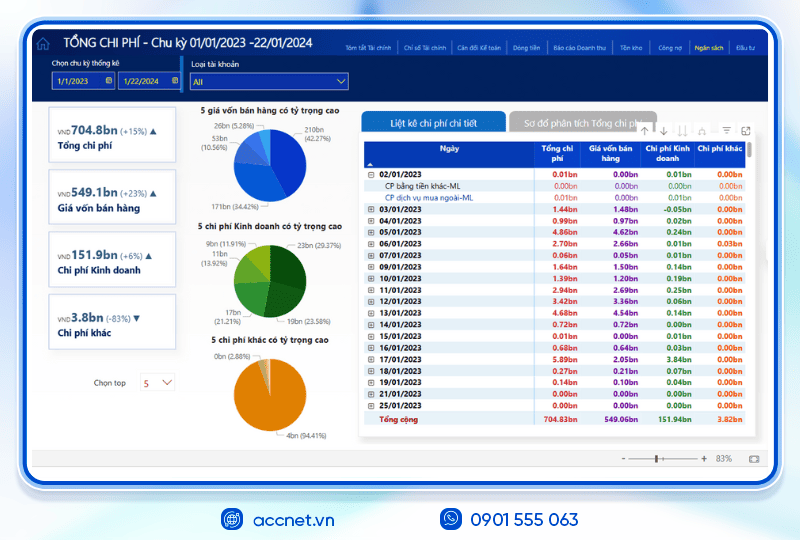

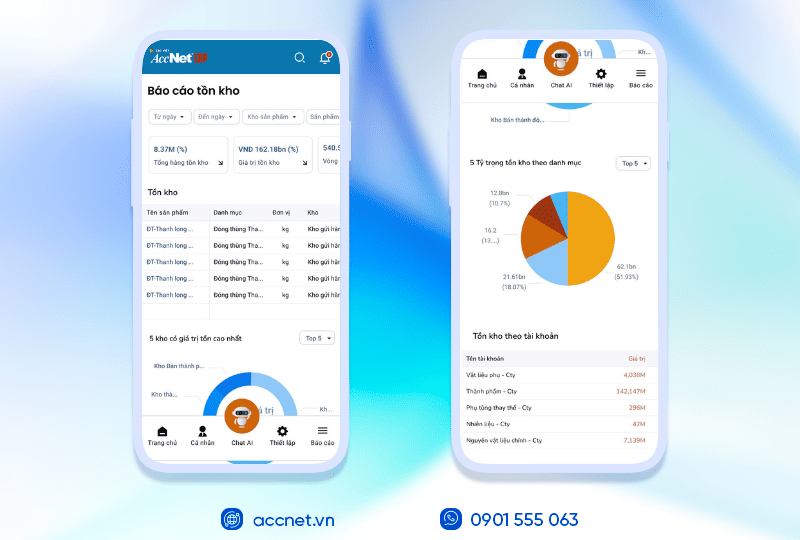

4. Giải pháp công nghệ giúp tối ưu quy trình xuất hàng - AccNet ERP

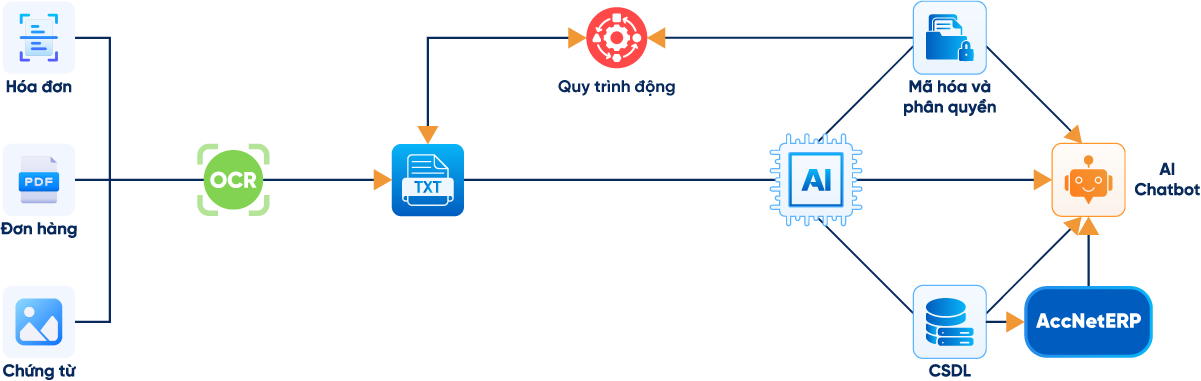

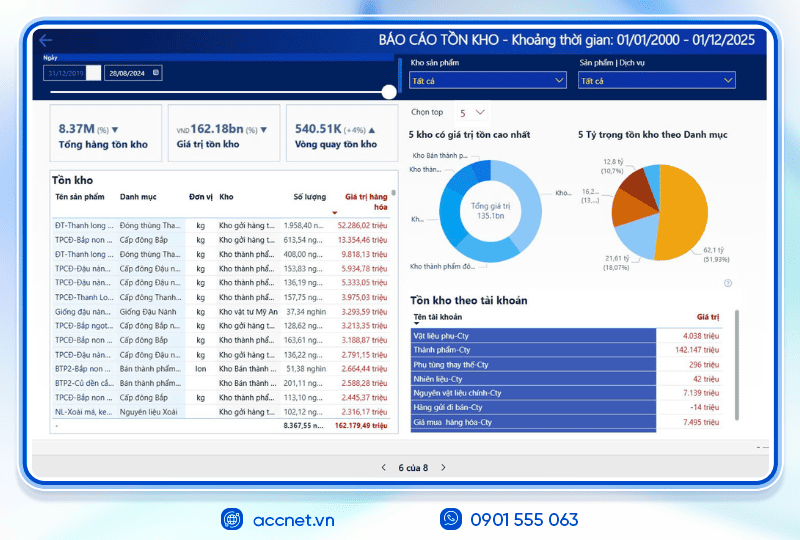

Việc áp dụng phần mềm AccNet ERP đang là xu hướng tất yếu trên thị trường số hiện nay khi giúp doanh nghiệp:

- Up to 70% data error when setting up warehouse.

- Save 30% processing time, recorded the data.

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI” Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp: AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn. ✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát” ✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI ĐĂNG KÝ NHẬN DEMO NGAY Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng ✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp ✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Quy trình xuất kho đóng vai trò quan trọng trong việc tối ưu quản lý hàng hóa, tính chính xác cho sổ sách kế toán. Doanh nghiệp cần xây dựng một quy trình xuất hàng chuẩn hóa, kết hợp với giải pháp công nghệ như phần mềm AccNet Inventory. Đừng để quản lý kho trở thành gánh nặng - Hãy trải nghiệm ngay phần mềm AccNet ERP!

CONTACT INFORMATION:- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: