Export warehouse material for manufacturing products là một khâu vô cùng quan trọng giúp quá trình sản xuất diễn ra liên tục. Quản lý tốt quá trình này sẽ giúp doanh nghiệp duy trì đủ nguyên liệu cho sản xuất, tránh thất thoát tài sản. Bài viết này, AccNet sẽ cung cấp cái nhìn chi tiết về cách hạch toán, quy trình xuất kho vật liệu khi doanh nghiệp quản lý chặt chẽ quá trình này.

1. Overview of export warehouse material for manufacturing products

Stock materials for product manufacturing is the process of supply of raw materials from the warehouse to the production department of the enterprise. This process ensures the raw material necessary to produce the product is removed from the warehouse, moved to production parts the right time/number of requests.

This is an important step in the supply chain's internal business, help in the manufacturing process takes place continuously, without interruption due to lack of raw materials.

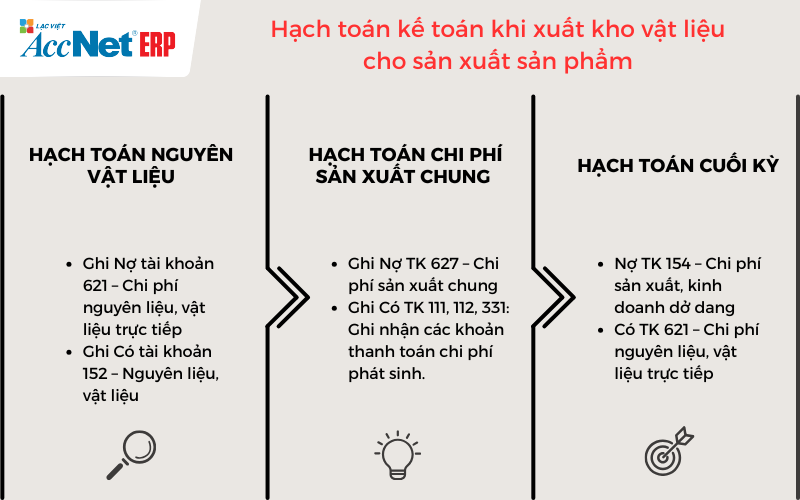

2. Accounting as stock material for manufacturing products

2.1. Accounting for stock materials

When businesses export raw materials to produce products, the accountant should record the reduction of inventory, shipping cost raw materials in production costs.

Journal:

- Debit accounts 621 – material Costs, direct material: Reflects the cost of raw material was used directly in the production process.

- Credited account 152 – Raw materials, materials: Reflecting the warehouse, reducing the number of raw materials.

For example: If the business of stock 500 kg of fabric was worth 100 million VND to clothing production, accounting entries will be:

- Debt TK 621: 100 million VND

- Have TK 152: 100 million VND

2.2. Accounting of production costs in general stock materials (if available)

If costs related to the transport, storage and losses arising in the process of storage of raw materials, the accountant should record added to the cost of joint production (TK 627).

Journal:

- Debit TK 627 – the Cost of joint production: recognition of costs incurred related to raw materials in the production process.

- Credited TK 111, 112, 331: Record the payment of expenses incurred.

Read more:

2.3. Accounting period-end

At maturity, the cost of raw materials is accounted for in TK 154 – the Cost of production, unfinished business to determine the price of products.

Accounting period-end stock material for manufacturing products:

- Debt TK 154 – the Cost of production, unfinished business: the whole set of production costs.

- Have TK 621 – material Costs, direct material: The raw material costs in the cost of production products.

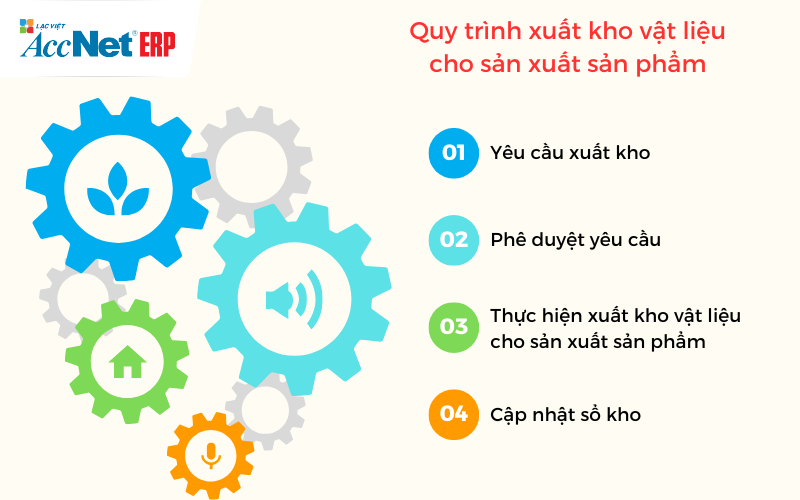

3. The export process inventory materials for manufacturing products

To the export process, the material goes on smooth, need to follow the specific steps below:

- Step 1: request inventory

Production department will set request. the material, listed complete information about the raw material should include: name, materials, quantity, unit, intended use, the time of the request.

- Step 2: Approval request

Inventory management or production management department will review, approve, votes required to inventory. The approval is based on factors such as: the amount Of material remaining inventory; the reasonableness of the request compared with planned production; Check the accuracy of the relevant information.

Read more:

- Công nghệ RFID trong logistics kho vận giúp truy xuất nhanh chính xác

- Way inventory management with QR Code giảm sai sót và tiết kiệm thời gian

- Hướng dẫn chi tiết cách định khoản account inventory

- Step 3: perform warehouse material for manufacturing products

Warehouse staff conduct. the material according to the requirements. This process should be done carefully, keep a record full information about material, quantity, date of stock and receiver unit.

Warehouse staff must ensure that the raw materials warehouse export right quantity, quality, time confirmation, along with parts of receipt.

- Step 4: Update window warehouse

Accounting warehouse/warehouse staff need to update the number of inventory remaining at the window, inventory or warehouse management software.

4. The documents related to the export warehouse material

- Warehouse: Recorded detailed information about the types of raw materials, quantity, unit price, total value of raw material export stock

- The inventory panel materials: According to reconcile the amount of material inventory.

- Report production: General information about the ingredients were, the amount of consumption in the production process

- Stock recommendation warehouse material for manufacturing products: Are parts manufacturing establishment when necessary raw materials, specify the type, amount, purpose of use

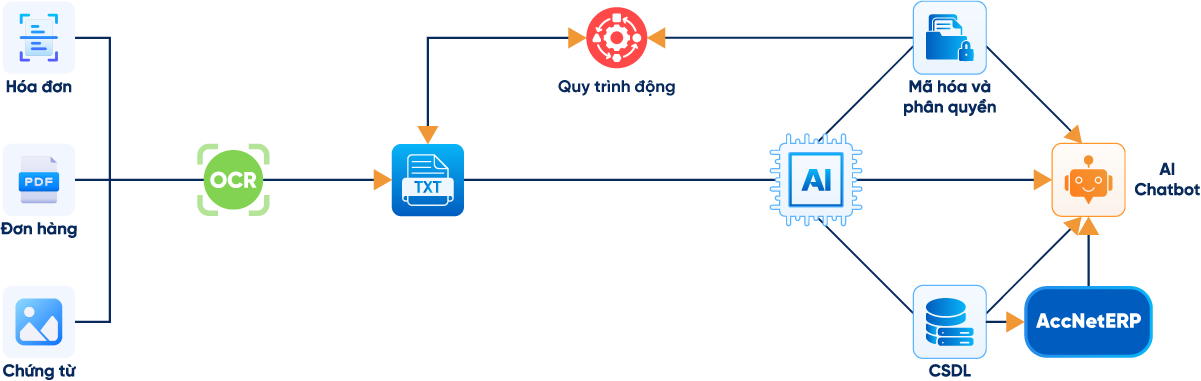

5. Quản lý xuất kho vật liệu dễ dàng với phần mềm Accnet ERP

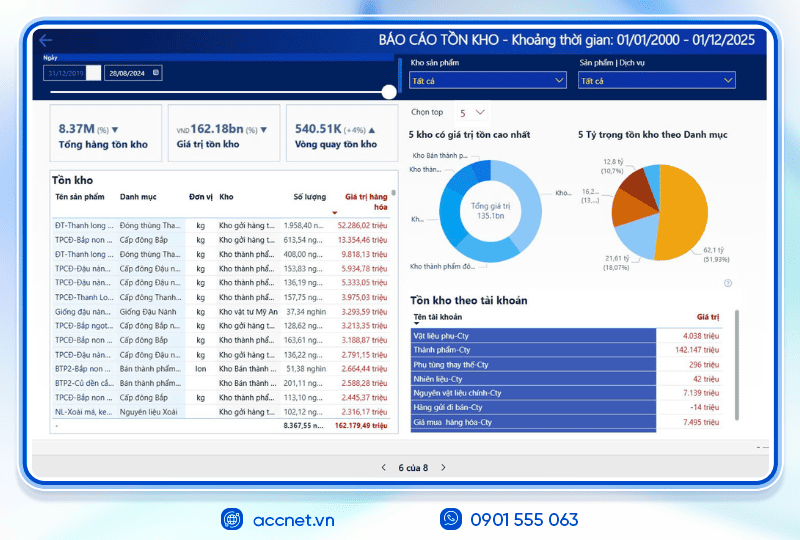

With phần mềm kế toán kho AccNet ERPbusinesses can automate the whole process of stock as:

- Set up warehouse

- Update data inventory in real time

- Tightly control the flow of material.

Các phần mềm quản lý kho giúp giảm thiểu sai sót, tiết kiệm thời gian, đồng thời cung cấp các báo cáo chi tiết để dễ dàng quản lý kho, tối ưu hóa chi phí sản xuất. AccNet ERP is modern solutions, business support warehouse management efficiency, improve business performance.

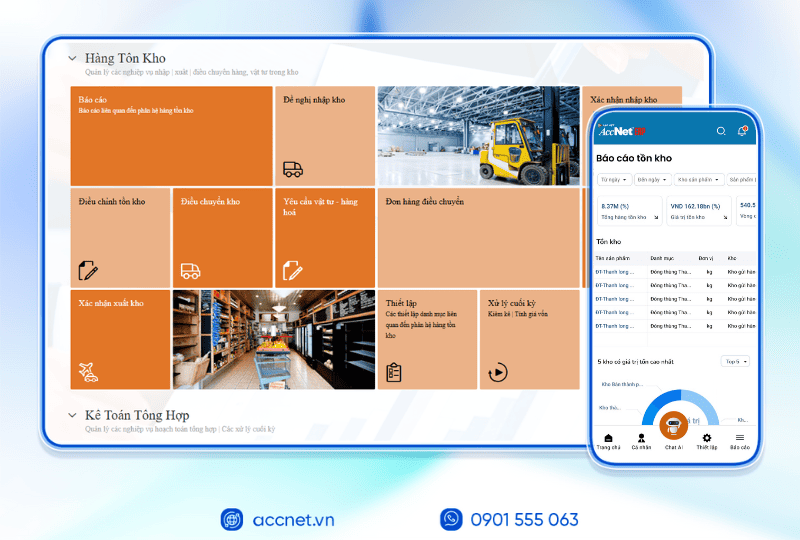

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

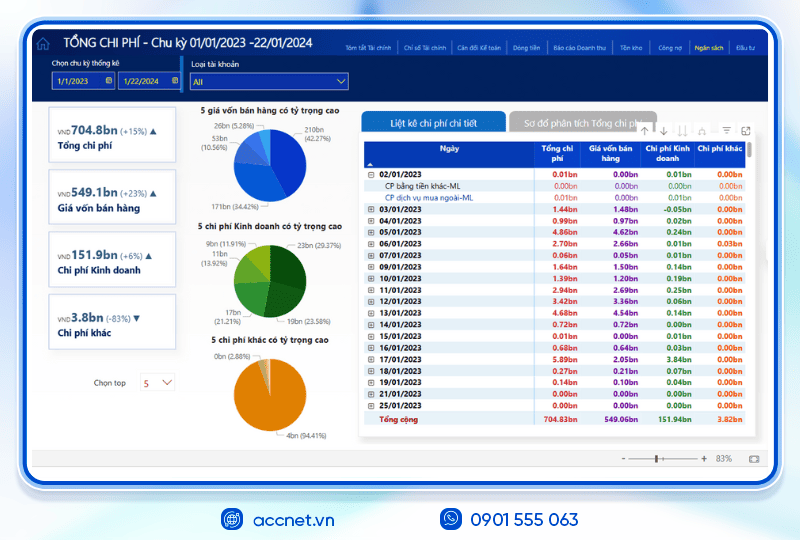

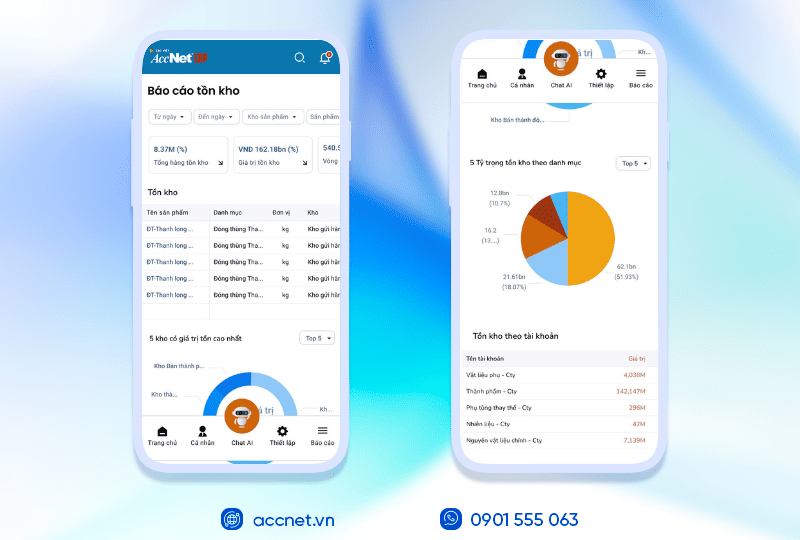

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Learn more:

- Instructions kiểm kê hàng tồn kho thực tế cho doanh nghiệp

- Solution quản trị tồn kho trong logistics hiện đại và hiệu quả

- Application nguyên tắc ABC trong quản lý kho hàng efficiency

Performance management process export warehouse material for manufacturing products to help businesses ensure production schedule. Understanding how accounting, the steps in the process, applying management solution that will help the business operate smoothly. I hope this post will bring useful information to support your business sustainable development.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: