RFID (Radio Frequency Identification) has emerged as a technology solutions and advanced business automation and inventory management. According to the report of Zebra Technologies, the business applied RFID has increased by 30% performance inventory management, reduce by 25% the rate of loss of goods. So RFID in warehouse management is what? How it works, benefits specific happen? This article AccNet will provide detailed insight solutions deployed RFID technology for business.

1. RFID in warehouse management is what?

1.1. Definition RFID

RFID stands for Radio Frequency Identification, technology identification, object tracking via radio waves. RFID works based on the mechanism wireless data transmission from the RFID tag to the RFID reader, which allows updates information of goods.

Different than traditional bar code, RFID does not need to scan directly each product that still can read information from, and simultaneously handle multiple RFID tags at the same time.

1.2. Main components of RFID system

System RFID in warehouse management consists of 4 basic components:

- RFID tags (RFID Tags)

- RFID reader (RFID Reader)

- Antenna RFID

- Management software, RFID

1.3. Principle of operation of RFID in inventory management

RFID systems operate in 3 basic steps as follows:

- Step 1: RFID reader radio broadcast to activate the RFID tag in range.

- Step 2: RFID Cards back information that has storage (item code, quantity...) about reader.

- Step 3: Data from the read head is moved to the warehouse management software to update the data in the system.

2. The process to deploy RFID in warehouse management business

Step 1: Survey reviews the current state of warehouse

Before deploying RFID, enterprises need to assess the scale warehouse, demand management: Classification of goods, specify the number of rows need to tag RFID.

Identify specific objectives:

- Automation warehouse inventory.

- Enhance the precision management of goods.

Step 2: selecting equipment, software, RFID match

The selection of equipment, the appropriate software is vital steps to deploy RFID in warehouse management.

RFID card:

- Passive tag: Suitable for warehouse, static, low cost.

- Card active: matching goods mobile, capable of transmitting far.

RFID reader:

- Reader fixed for regional export - import bank.

- Portable reader for the inventory quickly.

Management software, RFID: Integration with accounting software repository, the existing ERP system.

Read more:

Step 3: deploy tagged RFID in warehouse management

Mounting RFID tags on goods: Card is fixed on the shipment, shelves/packaging products. Install RFID reader:

- Put RFID reader in critical areas such as the warehouse door area inventory.

- Connect reader system with management software to record, data processing.

Step 4: staff Training and test operation

Staff training: a guide employees to use equipment RFID reader.

Running test system:

- Test the ability to record data processing.

- Detect, troubleshoot technical errors, if any.

Step 5: evaluate, optimize system RFID in warehouse management

After deployment time, businesses need to:

- Check the accuracy, processing speed, the ability to sync data.

- Upgrade equipment/software if necessary to meet the needs extension warehouse.

3. Benefits of RFID applications in inventory management

3.1. Enhanced accuracy in inventory

- RFID helps enterprises eliminate errors commonly encountered in inventory tradition.

- No need to scan each product as barcode, RFID can read multiple cards in a single scan.

- According to the report of Smartrac, RFID technology helps to improve accuracy in inventory up to 99.9%.

3.2. Process optimization, import - export goods

RFID in warehouse management, process automation and warehousing, and inventory, help businesses:

- When goods are warehoused or export warehouse, the system automatically recorded, updates to the software.

- Compared with the recording manually or scan the barcode of each product, RFID helps shorten the process by up to 50%.

3.3. Minimize loss of goods

RFID allows tracking, monitoring goods and accuracy, help to limit the loss.

- RFID helps businesses determine the exact location of goods in the warehouse.

- The system will signal when it detects goods deviations, being moved illegally.

3.4. Performance-enhancing inventory management, cost savings

- Minimize the cost and duration data processing.

- RFID in warehouse management helps businesses manage commodity science, discovery cargo backlog.

4. RFID applications in the field of warehouse management business

4.1. Inventory management of raw materials

RFID is applied effectively in the management of the storage of raw materials, particularly in the business of manufacture:

- Mounting RFID tags on each batch of raw materials to automatic updates information export - import repository.

- Based on data from system RFID in warehouse management, business easily forecast the amount of raw materials need to enter.

4.2. Inventory management of finished products

- Automatic updates of top quality wholesale goods, always ready.

- RFID helps businesses properly check the code goods, quantity of goods when delivered to the customer.

4.3. Inventory management retail

RFID is the ideal solution for retail businesses, where there are large cargo.

- RFID helps to check the amount of inventory, sales, run, inventory long day.

- When the amount of inventory drops below the minimum level, the system will automatically alert to timely enter the restaurant.

Read more:

5. The difficulty when deploying RFID

5.1. The cost of the initial investment is high

The deployment of RFID systems in inventory management requires the cost of the initial investment is quite large, including the cost of buying RFID card reader management software, equipment and infrastructure.

Solution:

- Start with area warehouse important or items have value to control investment costs.

- Business card can be used passively for goods static to save costs.

- Select software inventory management features integrated RFID will save cost in comparison with the deployment of independence.

5.2. The ability to integrate with existing systems

Many businesses are using the warehouse management system/traditional ERP may have difficulty when integrating RFID.

Solution:

- Prioritize the software easily integrates with ERP, WMS (Warehouse Management System) in your current business.

- Construct a transition from the old system to the RFID data to be constantly updated.

5.3. Training staff to operate the system

Warehouse staff may have difficulty in getting familiar with RFID technology in inventory management.

Solution:

- Provide training on how to use RFID reader.

- Create reference to employees can easily lookup when needed.

- Team provide technical support in the early stages of commissioning.

Learn more:

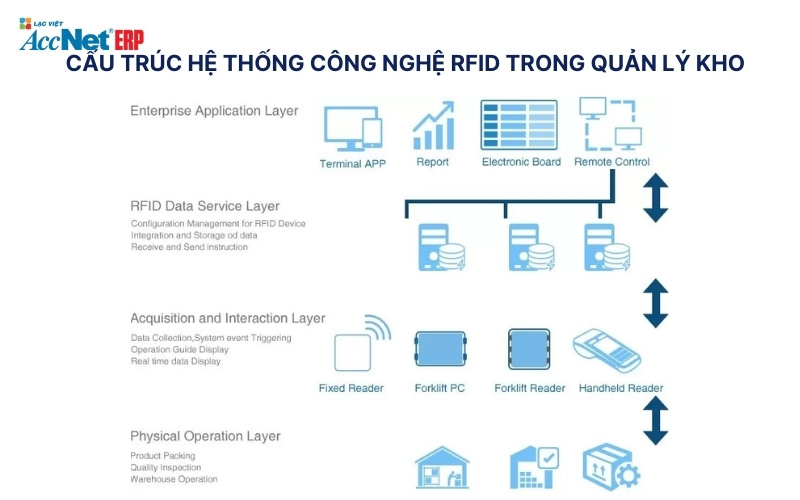

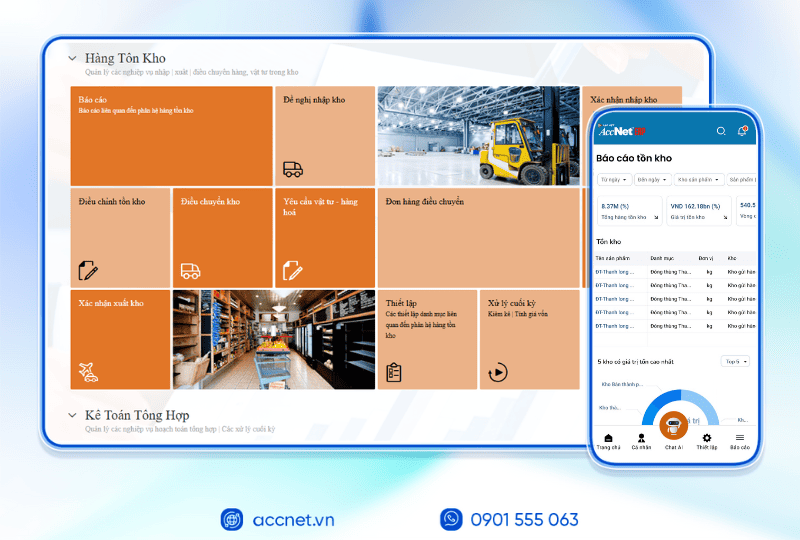

6. Ứng dụng RFID trong quản lý kho với AccNet ERP

Công nghệ RFID (Radio Frequency Identification) đang trở thành giải pháp tối ưu để theo dõi, kiểm soát và quản lý hàng hóa một cách chính xác, nhanh chóng. Thay vì phải quét từng mã vạch thủ công, RFID cho phép nhận diện và ghi nhận thông tin hàng hóa từ xa, giúp giảm sai sót, tiết kiệm thời gian và nâng cao hiệu quả vận hành kho. Việc áp dụng RFID giúp doanh nghiệp nắm rõ vị trí, số lượng và trạng thái của từng sản phẩm, đồng thời tăng khả năng truy xuất nguồn gốc khi cần thiết.

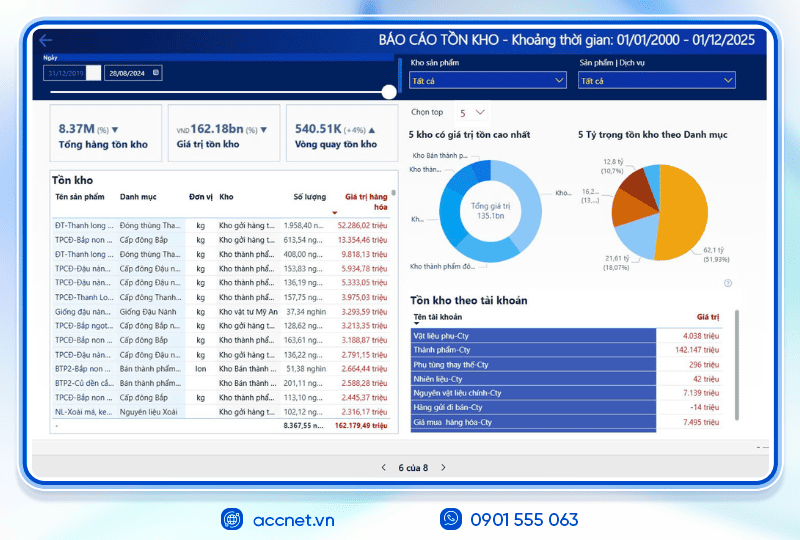

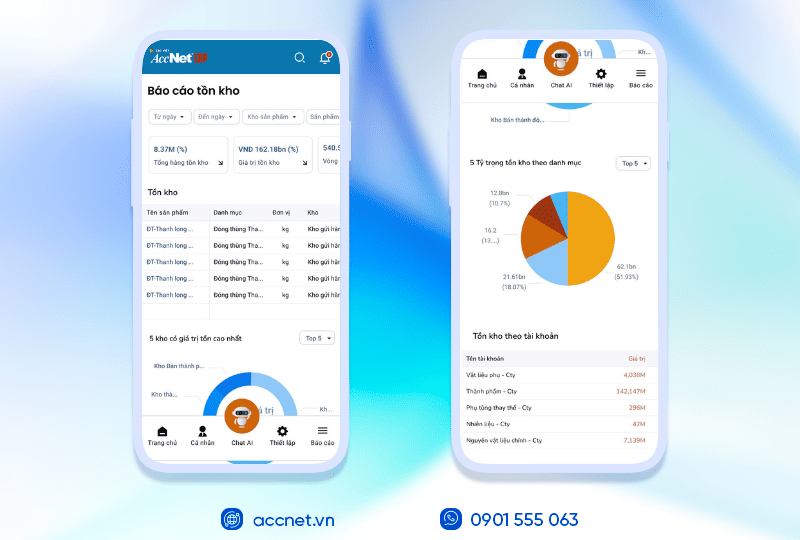

Tuy nhiên, để khai thác tối đa lợi ích của RFID, doanh nghiệp cần một hệ thống quản lý kho đồng bộ, có khả năng xử lý dữ liệu lớn và liên kết các nghiệp vụ liên quan. Đây là lúc AccNet ERP – phân hệ quản lý kho phát huy hiệu quả. Hệ thống tích hợp RFID cho phép tự động cập nhật tồn kho theo thời gian thực, từ việc nhập kho, xuất kho đến vận chuyển nội bộ. Nhờ đó, mọi thông tin về hàng hóa luôn chính xác, giảm thiểu sai sót do nhập liệu thủ công và tăng khả năng kiểm soát toàn bộ kho bãi.

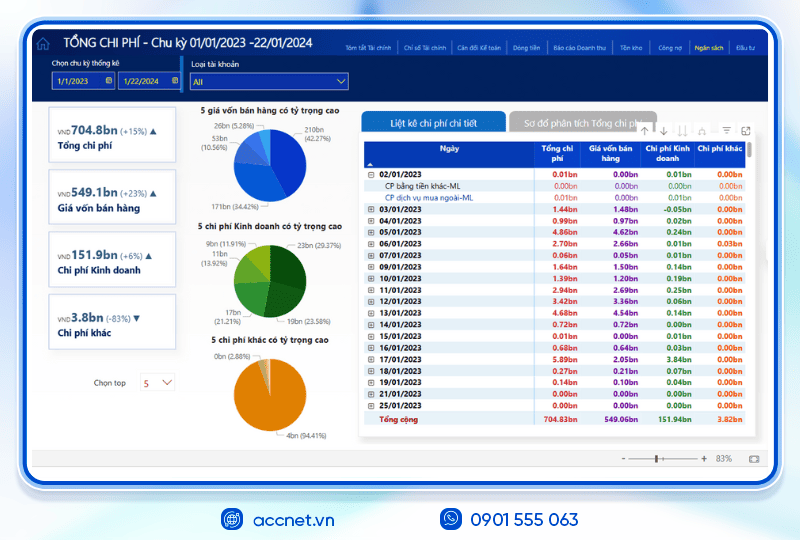

Ngoài ra, AccNet ERP kết nối dữ liệu RFID với các phân hệ khác như mua hàng, bán hàng và sản xuất, giúp đồng bộ toàn bộ luồng dữ liệu trong doanh nghiệp. Nhờ sự kết hợp này, doanh nghiệp không chỉ nâng cao hiệu quả quản lý kho mà còn tối ưu hóa quy trình vận hành, tiết kiệm thời gian và nhân lực, đồng thời tuân thủ các nguyên tắc kế toán theo Thông tư 133.

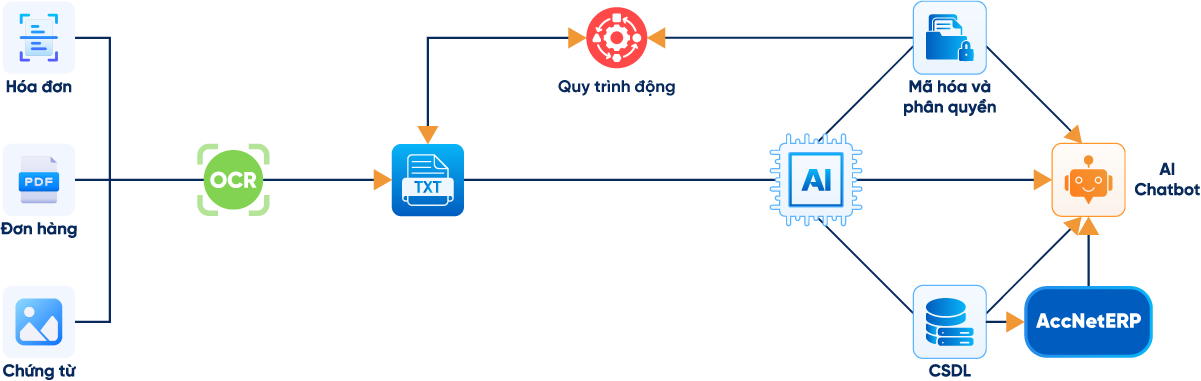

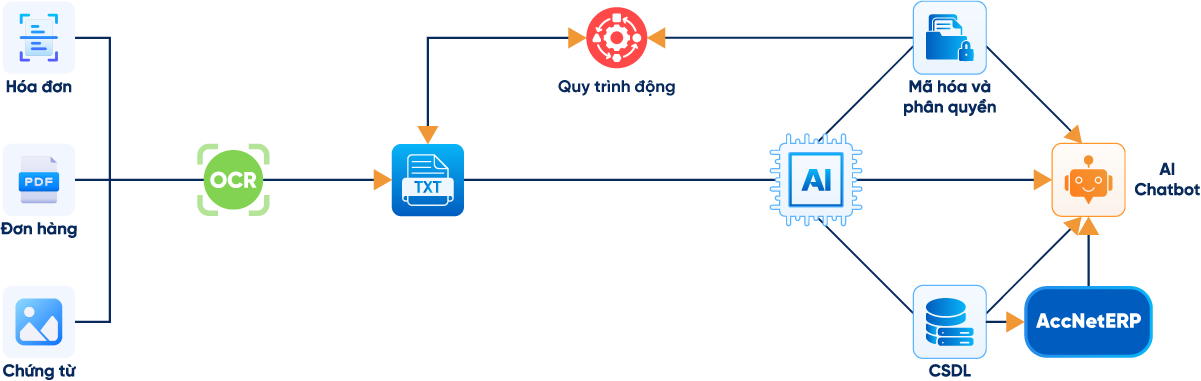

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI” Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp: AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn. ✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát” ✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI ĐĂNG KÝ NHẬN DEMO NGAY Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng ✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp ✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Công nghệ RFID trong quản lý kho giúp doanh nghiệp nâng cao độ chính xác trong kiểm kê, giảm thiểu thất thoát, tối ưu hóa quy trình nhập - xuất hàng hóa. Mặc dù chi phí đầu tư ban đầu có thể cao, nhưng lợi ích lâu dài về năng suất, hiệu quả, tiết kiệm chi phí sẽ hoàn toàn xứng đáng. Hãy trải nghiệm ngay giải pháp RFID kết hợp với phần mềm AccNet Inventory chuyên nghiệp ngay hôm nay!

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: