The number of inventory average is an important indicator to help businesses effectively manage quality goods. The calculation of this indicator helps the business determine the amount of the average during the accounting period, ensure enough goods to meet customer demand. So specific inventory average là gì và công thức tính như thế nào? Theo dõi bài viết sau của AccNet để được cung cấp thông tin chi tiết.

1. Inventory on average, what is?

Inventory average is calculated based on the number of inventory beginning and end of a business, then divide that average to get the number of inventory at the average in the states.Inventory average is an important indicator in the management of the inventory of the business, particularly in the manufacturing industry, retail and logistics. This index expresses the level of goods on average are in the inventory of the business in a given time period.

2. Formula for calculating inventory average precision

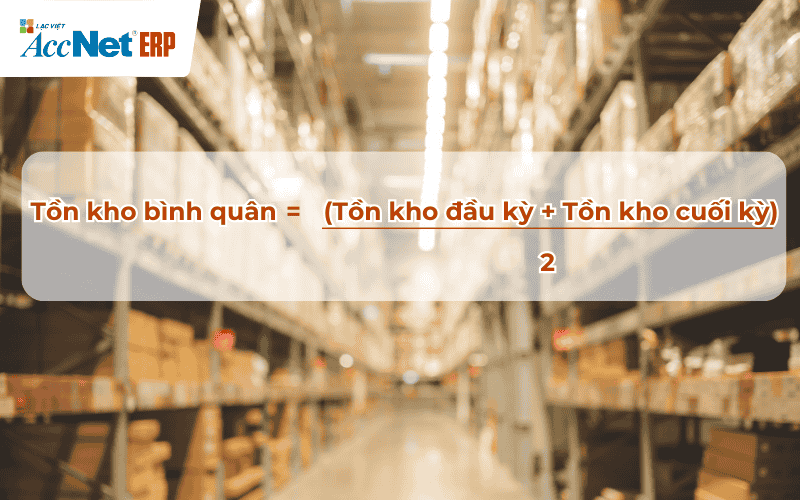

How to calculate inventory on average, the general formula is used as follows:

Formula: inventory average = (inventory, beginning of the period + inventory end of period) / 2

Explanation:

- Inventory at beginning of year: This is the amount of goods that businesses have available in stock at the beginning of calculations (usually the first month, quarter, or year).

- Inventory end of period: the Amount of inventory at the time of the end states after the fluctuations in import, export, goods in the states.

- On average, a split between the amount of inventory the beginning and end will give you the number of inventory average – is the average amount of goods business holds in all states that.

For example: Suppose company A has inventory the beginning of the period is 500 products, inventory, end of period is 700 products. How to calculate inventory average apply the formula above: Tồn kho bình quân = (500 + 700)/2 = 600. So, in the calculation of average inventory of the business is 600 products.

Business use formula for calculating the inventory average to measure the amount of inventory in a continuous manner throughout the accounting period, which in turn helps determine the amount of need to enter planning and inventory management in an effective way.

Read more:

3. Why calculating inventory levels, on average, is needed in business management?

The calculation of inventory average plays an important role in many aspects of business management, from managing cash flow and demand forecast to assess business performance.

Cash flow management

Inventory directly affects the cash flow of the business. Knowing the amount of inventory average helps businesses know the number of goods need to buy more, as well as when to reduce the amount of inventory to release working capital.

If the inventory is too high, capital is “buried” in the warehouse, can not be used for other activities such as investment, marketing, or paid employees. Conversely, if inventory is too low, the business may encounter the situation of not enough goods to meet demand, resulting in lost revenue.

Good management of inventory average help business adjust the level of goods logical and reduce operating costs as the cost of warehousing, storage of goods, the opportunity cost.

Demand forecasting and production planning

Inventory levels average is an important indicator to forecast demand and plan production efficiency. Through keeping track of inventory levels, on average, businesses can predict the level of consumption in the future, from that plan import or manufacture at the right time. Helps avoid excess inventory or shortage of goods caused losses for the business.

Evaluate business performance

Inventory index average is also a useful tool to evaluate the operational efficiency of the business. A business can manage inventory better will respond quickly to market demands without having the status of goods in the backlog too much or not enough goods to sell. From there, business performance will be improved, at the same time help improve the experience of customers when goods timely.

When the inventory level average is optimal, reflecting the ability to operate the efficiency of the enterprise, reduce unnecessary costs and help improve profitability.

4. Yếu tố ảnh hưởng trực tiếp đến hàng tồn kho bình quân

Speed consumption goods

Speed consumption is the most important factor affecting the level of inventory on average. Speed consumption goods as quickly, the amount of inventory will be constantly changing, from which the impact on inventory index average.

When the goods are consumed slowly, the amount of inventory will increase, towing costs of storage and preservation increase. Conversely, if the consumption rate is high, businesses need to plan to enter orders quickly in order to maintain the stability of the warehouse, avoid the inventory, the average fall in the level is too low, causing shortages.

Read more:

Production cycle/supply

Production cycle and supply also directly affect the amount of inventory average of the business. Manufacturing enterprises need to plan the supply of raw materials in accordance with the production cycle to ensure uninterrupted operation. If the cycle supply lasts or not stable, businesses must reserve more material than that inventory levels increased. For the commercial business cycle, supply of goods from supplier also affects inventory levels, especially in high season or when needs change suddenly.

Policy inventory management

Policy, inventory management of each business also has a decisive role to inventory levels, on average. The business has a policy effective inventory management often have the ability to adjust the amount of inventory a more flexible way to optimize resources. On the contrary, if the business is no process, inventory management, clear, easily leads to a situation of excess or shortage of inventory, negatively affect the inventory index average.

Learn more:

5. Cải thiện việc tính toán mức tồn kho trung bình với AccNet ERP

Using software inventory management

Warehouse management software is great not only help businesses track inventory accurately, but also supports the calculation of inventory on average, in an automatic way.

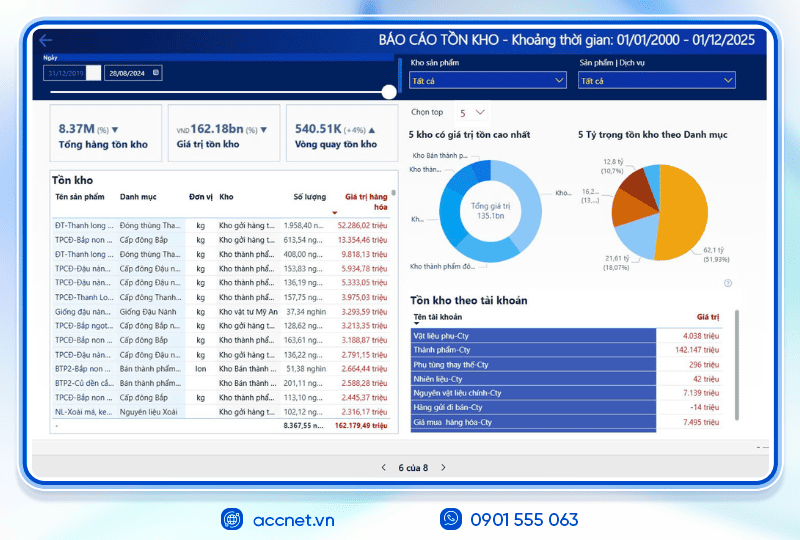

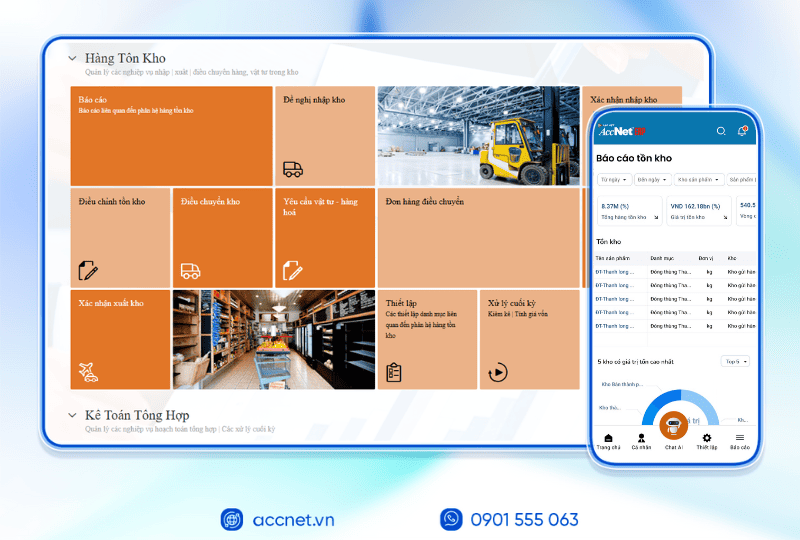

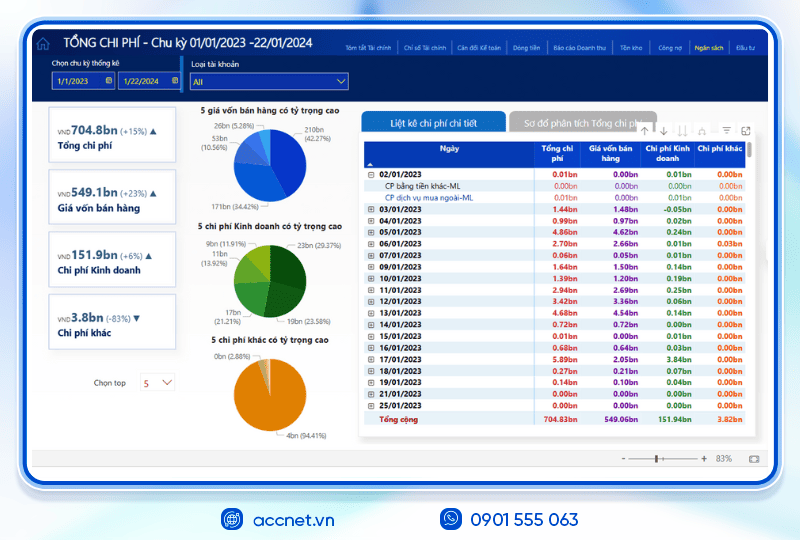

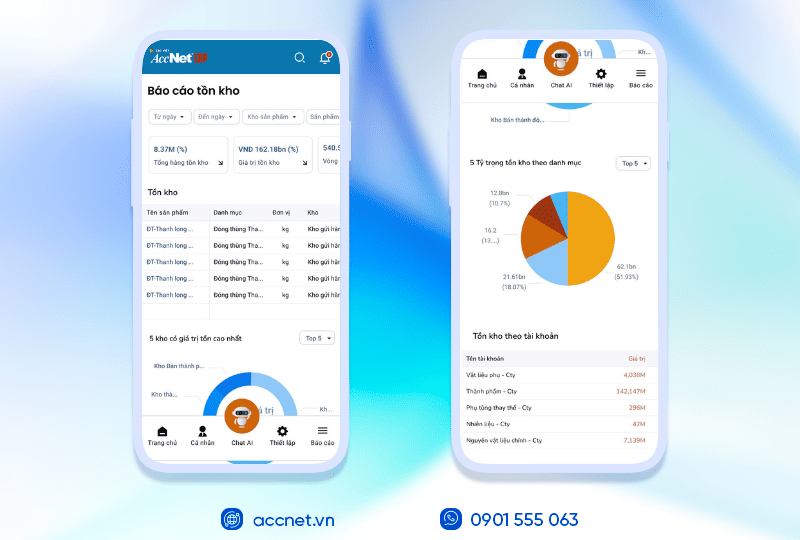

Phần mềm AccNet ERP giúp doanh nghiệp dễ dàng kiểm soát và tính toán hàng lưu kho trung bình thông qua các tính năng ưu việt. Hệ thống cung cấp thông tin chi tiết về quy trình nhập, xuất hàng hóa như báo giá, đặt hàng, thực nhận, giao hàng, xuất hóa đơn, giúp theo dõi toàn bộ chu trình một cách minh bạch. AccNet ERP còn có khả năng kiểm soát lô hàng, theo dõi hạn sử dụng, nguồn gốc và tính tuổi hàng tồn kho, giúp tối ưu việc quản lý.

Với giao diện dễ sử dụng và khả năng tích hợp dữ liệu, AccNet ERP giúp doanh nghiệp có thể tối ưu hóa quy trình quản lý kho mà không gặp phải các vấn đề về lỗi nhập liệu thủ công hay chênh lệch số liệu. Hệ thống quản lý kho hiện đại là giải pháp toàn diện, giúp doanh nghiệp dễ dàng kiểm soát tồn kho, cải thiện năng suất và giảm thiểu sai sót trong quản lý hàng hóa.

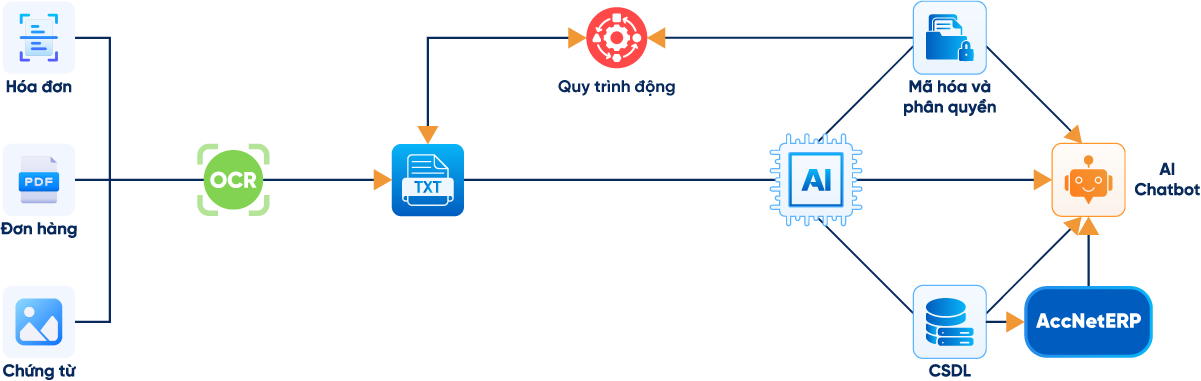

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Optimal process inventory

A way to improve the calculation of inventory average is optimized process inventory. Warehouse inventory periodically will help businesses get data inventory beginning and end properly, thereby improving the accuracy of the calculation, inventory average.

Business needs to make an inventory of goods according to specific schedule (month, quarter, year) in combination with the use of modern tools such as bar code, QR Code to minimize errors. The digitization process inventory will help reduce the time and effort in management, at the same time providing accurate information on the amount of current inventory.

Planning based on data

The planning based on the data inventory, consumption goods in the past will help businesses predict accurate future demand, from which adjust inventory levels accordingly.

Businesses can use tools to analyze data to track trends in consumption and the volatility of the inventory. This helps make the decision more accurate about when need import or adjust inventory levels to avoid the excess or deficiency.

Refer to: Dấu hiệu hàng hóa tồn kho giảm và tác động đến kế hoạch sản xuất

Calculate inventory average not only to help businesses grasp the situation of goods in warehouses, but also plays an important role in the optimization operation. By improving the calculation of inventory levels, on average, businesses can ensure inventory levels reasonable, from which optimize cost, enhance the ability to respond to market demands quickly and efficiently.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: