Costs of storage increasingly occupy a large proportion in the cost of operating the business, apply strategic commodity classification is a mandatory step to optimize capital , improving the quality of services. Principles ABC in warehouse management is classified tools, simple but effective, which helps enterprises to focus resources for those items that contribute the most value , reduce costs for the less important items. This article — written for business is to learn , to develop solutions inventory management — towards a tutorial enforce specific, easy to apply , ready to take on the ERP/WMS.

1. Concepts principles ABC in warehouse management

Basic principles

Principles ABC divide the whole catalogue of goods into three groups according to the degree of contribution value (usually revenue or profit):

- The A — team, high-value big influence on business results;

- B — group average;

- C — group, the low value, accounting for the majority in number, but contribute little of value.

The core idea is derived from the Pareto Principle (80/20): a small percentage of the products often create the majority value. Practical application, the business can choose different thresholds (for example A = 70-80% of the value, B = 15-25%, C = 5-10%), depending peculiarities industry.

Classification criteria

By default, most common criteria is the value used annually (Annual Usage Value) = (quantity consumed/year) × (selling price or cost of capital). However, to be more exact, businesses can consider:

- Gross profit (gross margin) instead of revenue;

- Cost, ordering cost, storage, shipping cost;

- The risk of damage/expiry (for perishables).

The selection criteria must reflect management objective: maximize profit, reduce the capital stock, or increase the level of customer service.

Read more:

2. Implementation guide principles ABC in warehouse management — step by step realistic

Below is the process execution step by step, practical for business, ready to deploy in Excel or integrated into ERP/WMS.

Step 1 — data Preparation (required)

Collect data for each commodity code (SKU):

- Code/ product Name, unit;

- The number of consumption/year (or the warehouse of the year);

- The sale price or capital/unit;

- Additional information: lead time, supplier, storage location, limited use (if any).

Note: data must be a data “remove” — remove SKU no activity or insider trading does not reflect the real consumption.

Step 2 — Calculate the value using

Create column: AnnualValue = QtyPerYear × UnitPrice. For example Excel formula (with Qty in column B, the Price in column C, row 2):

D2 = B2 * C2

The total value of the entire stock: =SUM(D:D)

Step 3 — Arrange , calculate the cumulative percentage

- Sort the list by AnnualValue descending.

- Create column Pct = D2 / TổngGiáTrị , column CumPct = cumulative sum of Pct. Excel template for CumPct (row 2):

E2 = D2 / $D$TOTAL

F2 = E2

F3 = F2 + E3 (copy down)

Or use =SUM($D$2:D2)/$D$TOTAL direct.

Step 4 — Determine the threshold A/B/C

- Read column CumPct in descending order: the SKU to when CumPct ≤ 0.70–0.80 A; next to 0.85–0.95 is B; the rest is C.

- Depending on the industry or supply chain, adjustable threshold: for example, the pharmaceutical industry can choose A = 90% due to the safety requirements for pharmaceutical products.

Step 5 — set the management strategy for each group (summary)

- A: strict control, regular inventory, location take priority, contract preferred provider.

- B: periodic monitoring, flexible adjustment.

- C: optimize costs, reduce the frequency of inventory, consider purchasing or remove SKU less effective.

Step 6 — automation , periodically check

- With a large catalog, user reporting tools (PivotTable, script, or module ABC in ERP/WMS) to automatically classified according to the schedules (for example, updated every quarter or 6 months).

- Set KPI: % of the capital is located in group A, the number of days of inventory average A/B/C, frequency of restaurant A.

Tip rapid deployment principles ABC in warehouse management & the errors

- Tip: Always keep a history of at least 12 months in order to avoid discrepancies due to seasonal. If there are fluctuations, seasonality, combined later with XYZ analysis (to be presented in the next section).

- Common error: using retail sales data (POS) hasn filter return, enter the wrong price of capital, or not updated price change leads to classification errors.

3. Benefits when applied principles ABC in warehouse management

The application of the principle of ABC in warehouse management not only helps the business to arrange goods more scientific but also a direct impact on operational efficiency, profitability , flexibility in the supply chain.

Resource optimization , cost storage

One of the biggest advantages of the ABC method is to focus resources on groups of rows have a value of high (group A). Instead , inventory management, evenly entire goods, enterprises need to:

- Cornered manpower, time , cost, for group A – where contributions to 80-90% of the total value of inventory;

- Reduce costs of storage and preservation for group C, where accounted for the largest amount, but less impact on profit;

- Leverage warehouse space more efficiently sort of group A at the central location, easy to grab, easy to control.

This helps businesses save an average of 15-25% of the cost of operating it each year, according to statistics from the units were deployed system management ABC fact.

Read more:

Improve operational efficiency , control

Classification of goods according to the group to help businesses adjust the frequency of inventory , inventory levels, suitable to each type.

- Group A was control in real time, often collated;

- Group B inspection periodically, monthly or quarterly;

- Group C just inventory the basic application process is lightweight.

The gradation helps parts logistics avoid “manage spreading” — just save manpower and reduce the risk of loss.

Improve the ability to forecast decisions

Principles ABC in warehouse management provides quantitative data clear for managers: products should investment products, which should be removed. Thanks to continuous monitoring, the quantity demanded of each commodity group, the enterprise:

- Forecast demand more accurately;

- Planned goods, buy raw materials, or pre-order cyclic;

- Make decisions sale price , marketing strategy, international more.

In particular, when combined with ERP or warehouse management software smart, this data becomes the foundation to build dashboard admin inventory service executive , department of planning – Supply.

Optimized supply chain , supplier relationship

The defined group of key help businesses select , negotiate more effectively with suppliers:

- Group A: long-term contracts, quality priority , on time delivery;

- Group B: contract flexibility, competitive price;

- Group C: may the best suppliers or buy through agents, intermediaries to save costs.

Thanks to that, the supply chain is streamlined, flexible , proactive than before market volatility.

Enhance customer experience

With the group of A – the product strategy, ensuring goods are always in stock to help businesses maintain rate customer service (service level), avoid separations , delivery delay.

At the same time, of group C can be used to make gifts, promotional goods to stimulate demand, increase brand awareness, which does not affect profits.

4. Strategic management details for each group of goods

After you have completed the classification according to the principle of ABC in warehouse management, the design of management strategies separately for each group is step decide the efficiency of the whole model.

Group A — product strategy, high value

This is a group of “backbone” of the business, often only 10-20% of the total number of SKU, but created to 80-90% of the value of inventory. Strategy management group A consists of:

- Strict control: adopt the technology bar code or QR Code, check statistics real-time automatic alerts when the inventory is below the safety threshold.

- Location preference: layout in areas accessible within the vicinity shipment to shorten the application processing time.

- Plan supply closely: set the survival minimum – maximum, management, batch or serial to traceability.

- Coordinate related departments: combination of inventory, purchasing , marketing to accurately forecast demand, especially with products that have seasonality.

Businesses should view the group A is the administration area in particular – need to invest in both technology and human resources to avoid a disruption in the supply chain.

Learn more:

Group B — intermediate products

Group B usually has an average value, which accounts for about 30-40% of the number of goods , contribute 15-25% of the overall value. Strategy management group B:

- Inventory flexibility: track by month, to maintain quality inventory sufficient to meet fluctuating light.

- Inventory periodically: 't need constant supervision, but should check every quarter to update the actual status.

- Flexible price policy: can gross group B into the sales program with group A to increase the rotation of inventory.

- Track trends: analysis of consumption data to detect potential products can be moved up to group A or decrease the value relegated to group C.

Group B should be considered as the region most versatile in the storage system, easy to adjust according to changes of the market.

Group C — value products, low bulk

Whether amounting to 50-70% of the catalog, group C only contribute 5-10% of the value of inventory. Strategy management group C:

- Optimal costs of storage: Reduce the frequency of inventory, apply cycle automatic ordering or purchasing periodically.

- Reduced storage area: layout separate area or storage in the cluster, avoiding occupy the space of group A, B.

- Evaluate the effectiveness periodically: If the product is less rotated or not to bring a profit, should be removed from the list or use as promotional items.

- Trigger strategy, sales support: Pooled group C with other products (combo, gifts) to speed up the consumption of brand identity.

Group C should be administered in a neat and space saving but still ensure data accuracy statistics service, financial reporting , investment decision later.

5. The solution application software principles ABC in warehouse management

Many ERP software , WMS has integrated functionality ABC analysis to help automate , standardize the whole process. Below are some popular solution in Vietnam:

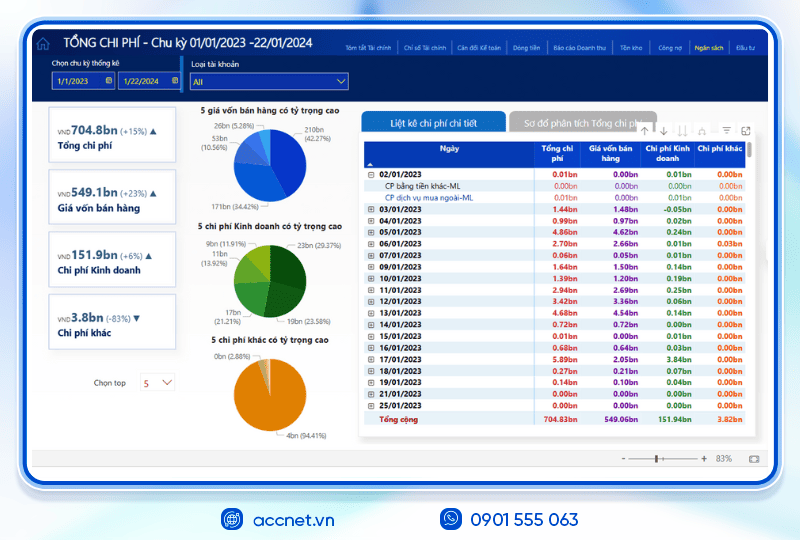

AccNet ERP

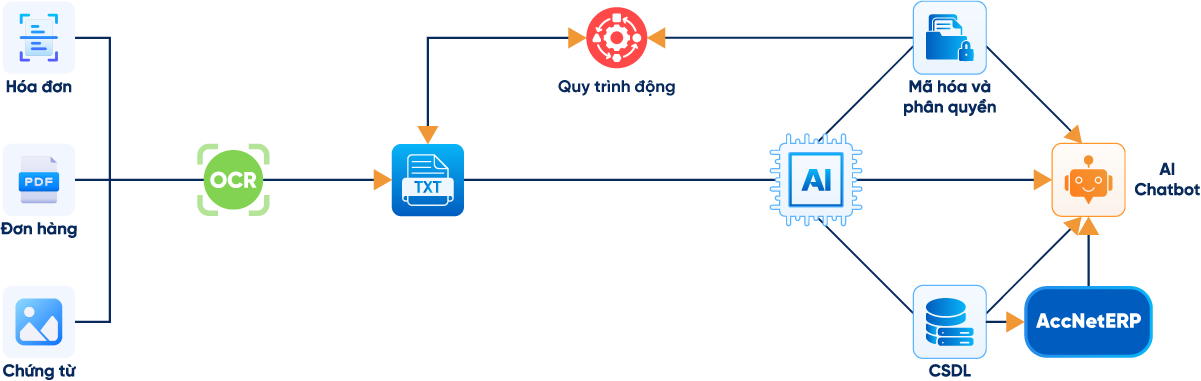

To achieve high efficiency in inventory management, the business can consider solutions AccNet ERP – management software, accounting , warehouse modern by Lac Viet development. AccNet ERP help:

- Automatic analysis , commodity groups according to the principle of ABC – XYZ.

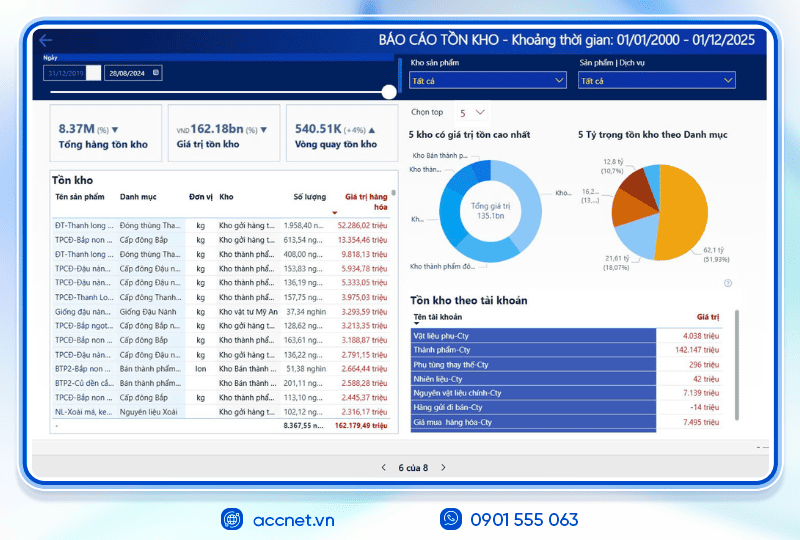

- Track inventory realtime between the branches.

- Direct connection with accounting, sales , purchase.

- Provide reports, inventory, financial reports , inventory alert, intelligent.

This solution is particularly suitable for business, manufacturing, trade, distribution, want to digitize processes, optimize costs , increase performance and inventory management.

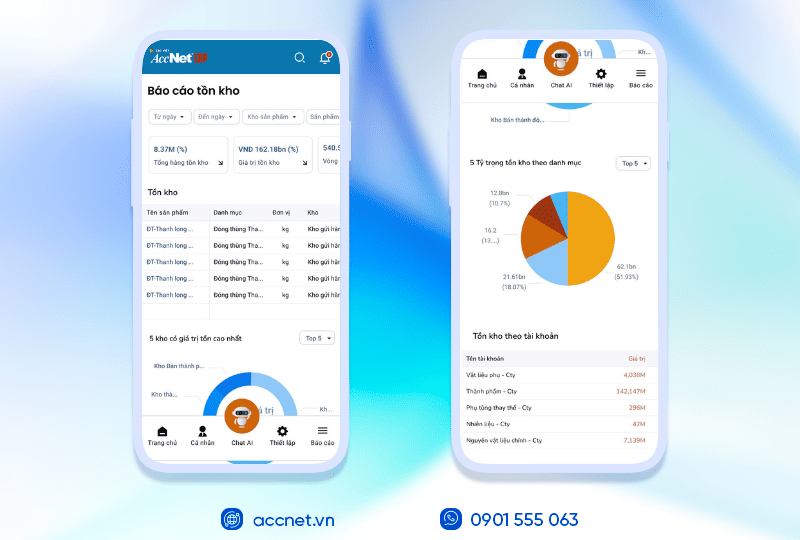

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

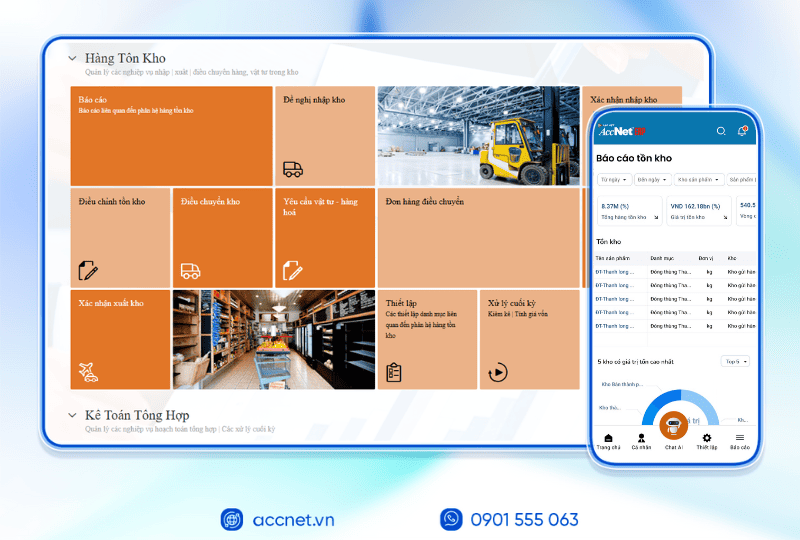

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

AritoERP

ERP software with comprehensive modules: Financial accounting, Purchase, Sales, Inventory, CRM, Production, HRM, Approval, E-Commerce. Highlights:

- Automate price calculation capital investment accurately.

- Store detailed information supplies (location, serial number, and suppliers).

- Set the inventory limit, minimum/maximum, avoid stagnant capital.

- Custom flexible according to the process characteristics of each business.

1C:Company Management (1C Vietnam)

ERP solution open , flexible, connect all the parts in the business. Feature highlights:

- Automates the entire process from sales, purchase, production, warehouse to accounting.

- Set the inventory limit , alerts, teen top.

- Supported vouchers , inventory quickly, reduce errors, data.

MISA AMIS Warehouse

Solution inventory management integrated smart AI principles ABC. Feature highlights:

- Automatic product classification A–B–C by value & frequency input.

- Cargo management according to unit calculator, QR code, batch number, expiry date, storage location.

- Support models, cold storage, temperature control , term use.

- Detailed reports, multi-dimensional according to each criterion.

WMS-X (VTI Solutions)

Warehouse Management system smart is designed for large-scale enterprise. Feature highlights:

- Automation ABC analysis , inventory alert.

- Show inventory in real-time (real-time).

- Alert when inventory is lower than a specified level.

Sapo

Platform management , sales, integrated channels (Omni-channel). Feature highlights:

- Daily stats out – in detail, get to know best-selling products.

- Connect the multi-channel (website, floor, e-COMMERCE, store, social networks).

- Support group analysis products according to sales performance support, inventory control optimal.

Principles ABC in warehouse management not only is a method of classification mere, which is the strategy tool that helps business inventory control smarter, reduce costs , enhance operational efficiency. When understanding the importance of each group of goods (A – B – C), businesses can:

- Optimal resources , storage area.

- To improve the accuracy of inventory report.

- Increase the speed of decision making in operations buy – sell – production.

However, to this principle really be effective, businesses need to have the technological systems to support, tracking, updates , data analysis, inventory realtime. This is where accounting software , management AccNet ERP becomes the optimal choice.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET ERP

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: