Inventory management accuracy and efficiency become the vital factor. Commodity diversity, large numbers , requires strict control of batch number, expiry date, origin requires the right business application of technology to optimize processes. One of the solutions to be more business current selection is inventory management with QR Code – technology helps automate the import, export, inventory , cargo tracking, enhance productivity , reduce errors in inventory management. The article below will provide a comprehensive view of the QR Code, compared to traditional barcodes, thus helping the business understand the benefits , the way into practical application.

1. Definition , basic Characteristics

Barcode (barcode)

Barcode or barcode one-dimensional (1D), is a technology commonly used in supermarkets, warehouses , logistics throughout the decades. A barcode standard, including the striped black – and-white alternating, sometimes accompanied by digit. Barcode mainly data storage format of the product identification quickly , inventory management in the traditional way. Device read is usually dedicated scanner, a data when printed will not be able to edit.

QR Code (Code quick response)

Other with barcode, QR Code is two-dimensional bar code (2D), which came out in 1994 by Denso Wave. QR Code includes the square , the black point on white background allows the storage of data is much larger than with barcode. In addition to numbers, the QR Code can contain text, URL, contact information, PDFS, photos, videos , even is a digitized complex. A special feature of the QR Code is the ability to scan from all directions (360°), can use the QR Code to update the data without the need to reprint the same time withstand the damaged part that still readable information.

Read more:

- Warehouse management software and supplies giúp tối ưu tồn kho doanh nghiệp

- Quy trình quản lý kho theo ISO giúp chuẩn hóa vận hành kho

- Process export warehouse material for manufacturing products details

2. Compare and Advantage of the QR Code in comparison with Barcode

| Criteria | Barcode (barcode) | QR Code (QR Code) |

| Structure | Linear code 1D | Code 2D matrix |

| Storage capacity | Under 100 characters, maximum 20 numbers | Up to more than 1500 alpha – numeric characters, max 7.089 numbers or 4.296-letter words |

| Types of data | Mainly numbers, read product value | Diversity: text, URL, contact, PDF, image, video |

| The ability to scan | Limit horizontally, a distance of 30 cm – 5 m | Flexible scanning every direction, range scanning custom size code |

| Durability/bug Fixes | Perishable smudging | Anti-damage, high reading is when damaged to ~30% |

| Reading device | Requires specialized equipment | Can scan with a smartphone, tablet, PDA |

| Abilities edit | Fixed, no editing after printing | Dynamic QR Code that can edit , update content |

| Application items small | Difficult to apply | Matching products small size, contains more information |

Review: The choice between barcode , QR Code depends on the business needs: if you need to store basic data, barcode still effective; if you want to inventory management, smart tracking, informative , increase accuracy, warehouse management with QR Code is the optimal solution.

3. Benefits of the application of QR Code in warehouse management

Inventory management application with QR Code is becoming a trend in many modern businesses, thanks to the ability to digitize , optimize the operation process. The integrated QR Code on inventory management brings the value following highlights:

Improve productivity and efficiency

Thanks to the ability to scan code fast, QR Code help staff reduce the time spent entering data manually, accelerate the manipulation import, export, inventory of goods. The process is done automatically on the management software, which allows to manage the quantity of goods greater than that which still ensures accurate. Fact, the app QR Code can raise the productivity of labor warehouse up to 30%, especially useful for businesses that have large amounts of goods.

Minimize errors, increase accuracy

Shipping from management manual to digital help minimize the errors caused by data entry or mistakenly products. Device scan the code to ensure product information is recorded homogeneous, reducing the error rate in inventory management can be up to 90%. Thanks to it, data inventory becomes more reliable , easier to control.

Read more:

- The work of inventory accounting trong doanh nghiệp sản xuất

- Application RFID in warehouse management giúp giảm thất thoát hàng hóa

- Phân loại tài khoản hàng hóa, nguyên vật liệu trong kho

Control , traceability

QR Code help businesses accurately track your shipment, product origin , duration of storage. Each QR code contains detail information about product name, SKU code, batch number, production date, expiry date, for quick access when needed. Thanks for the feature updates in real time, the inventory management can prevent the status of the error, expired, or lost.

Optimized operating costs

The digitization process inventory using QR Code help reduce costs , minimalist to the step inventory, import – export manually. Businesses can minimize the risk inventory excess or deficiency, from which optimize the cost of keeping goods , enhance business efficiency.

Support management decisions

Data is collected via QR Code serves not only stock but also provides information strategies for management. Statistical inventory, flow of goods , the report in real time to help decision makers quickly and accurately, from the ordering, distribution, and production planning.

4. Process warehouse management with QR Code (practical application)

To deploy inventory management using QR Code efficiency, enterprises need to establish a standard procedure includes the following basic steps:

Step 1. Set , assign QR code

- Generate QR code for each product through the warehouse management software WMS or ERP.

- QR code can store information, product name, SKU code, batch number, production date, expiry date.

- Stamp printing, QR Code printer for professional use stickers on products, packaging or storage location.

Step 2. Warehousing

- Scan the products QR code with your device PDA or mobile scanner.

- The software automatically recorded information , allocated storage location.

- This process helps employees to enter data quickly, minimize errors, than enter the hand.

Step 3. Export warehouse

- When required, e. scan the QR code to access the location information , the status of products.

- Updated software data inventory, create votes, cumshot, automatically, to ensure accuracy and transparency.

Step 4. Inventory

- Use your device to scan the QR Code to check the number of inventory.

- System for screening with software data, identifying the difference quickly.

- Thanks to features automatic process inventory become simpler and saves time.

Step 5. Manage warehouse location

- Attach the QR Code up shelves or storage area.

- Employee easily locate products, optimizing the flow of movement in the stock , reduce the search time.

Review: The deployment of QR Code in the repository not only speed operation, but also ensure the accurate data, helping businesses operate smart inventory, reduce costs , support effective decisions.

5. Challenges when deploying QR Code Solution future

Although inventory management using QR Code brings many benefits, but business still faces a number of challenges:

The downside , tough

- Requires visual display: the QR Code should be printed , put in place to scan. If clouded, blurred or broken, the scan will get stuck.

- No batch scanning: Current QR Code still requires scanning each product, can not completely replace the process control automated warehouse for large quantities.

- Cost of initial investment: deploy QR Code need a scanner device, printer, stamps, software, WMS/ERP , employee training, creating barriers of capital.

- Training systems integration: Transition from traditional management to the QR Code required duration of training , adjusting IT systems current.

- Data security: QR Code can be potential risks of collecting data illegally, although can be secured by a password or PIN code.

Learn more:

Future technology – RFID

RFID (Radio Frequency Identification) is considered as the next step, solve the limitations of QR Code.

- Scan do not need visual display: RFID read data remotely without the need to see live.

- Support batch scanning: Helps inventory fast all pallets or large warehouses that don't need to scan every code.

- Integrated automatic: RFID in conjunction with warehouse management system helps to automatically collect , store, data, improve accuracy , save time.

6. Tool , software, support warehouse management with QR Code

To deploy inventory management using QR Code effectively, businesses need to have:

- Warehouse management software (WMS/ERP): storage , data processing goods.

- Device barcode reader/QR Code scanner, PDA, smartphone, or tablet.

- Barcode printer: Printing stamp QR Code high quality.

- Network infrastructure , servers, data storage: Ensure continuous operation , information security.

Some popular solutions on the market today:

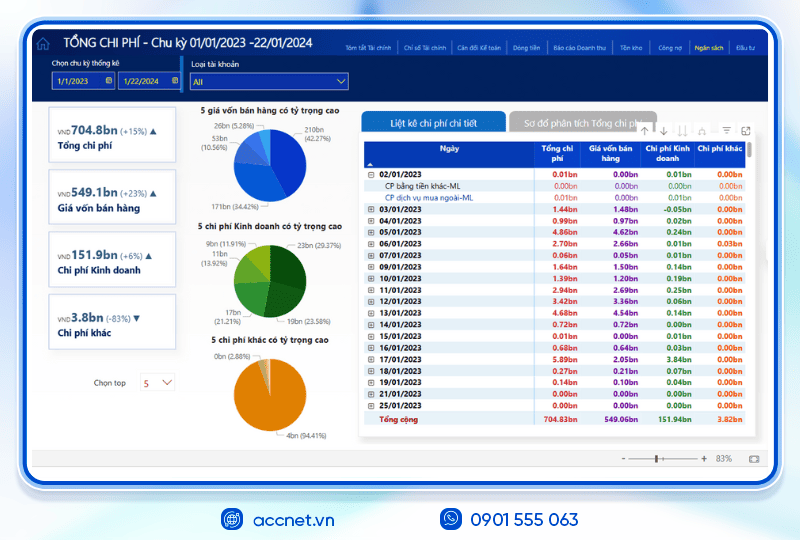

Solution – AccNet ERP

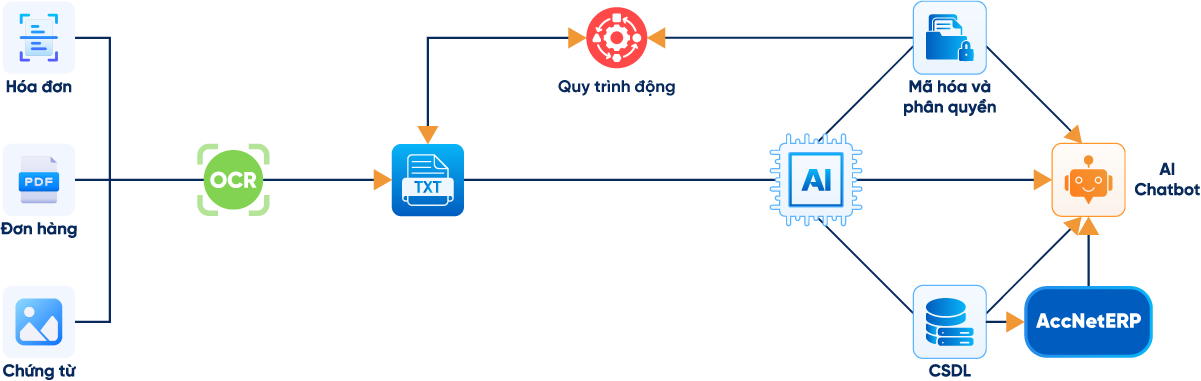

In the context of conversion of AccNet is ERP solutions, warehouse management, comprehensive for business Vietnam:

- Inventory management smart QR Code: process automation import – export – inventory, reduce errors and improve productivity.

- Integrates data in real time: Help quick decisions, optimize operating costs.

- Support multi-warehouse management: Fit medium business , small chain warehouse dispersed.

- Security , flexibility: allow dynamic QR Code, update product information without the need to reprint.

Thanks to these features, AccNet ERP helps businesses apply warehouse management with QR Code in an efficient way, at the same time ready to expand future technology such as RFID.

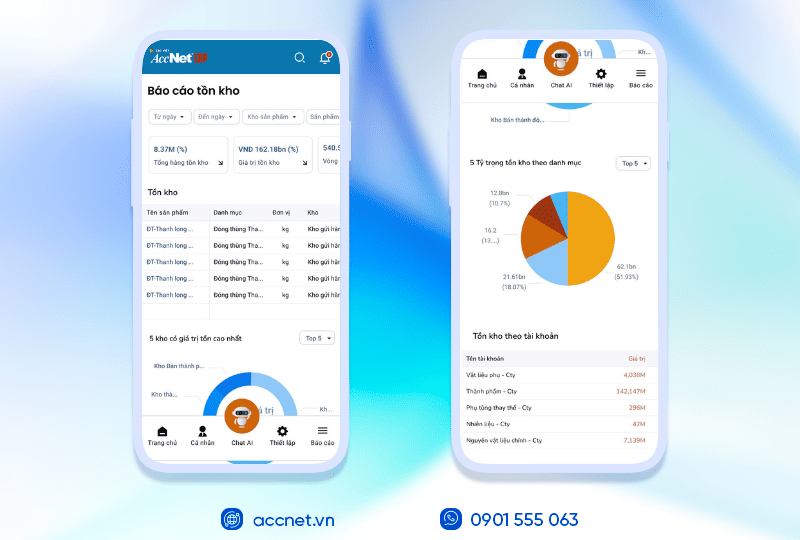

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI”

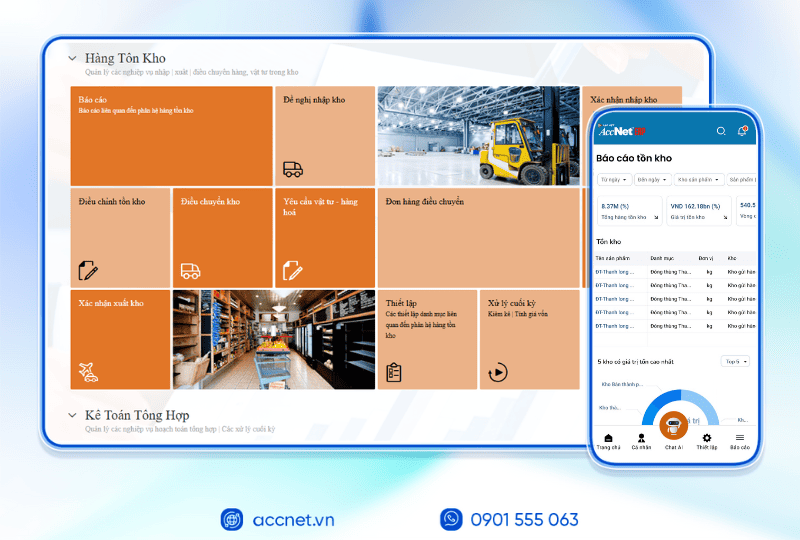

Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp:

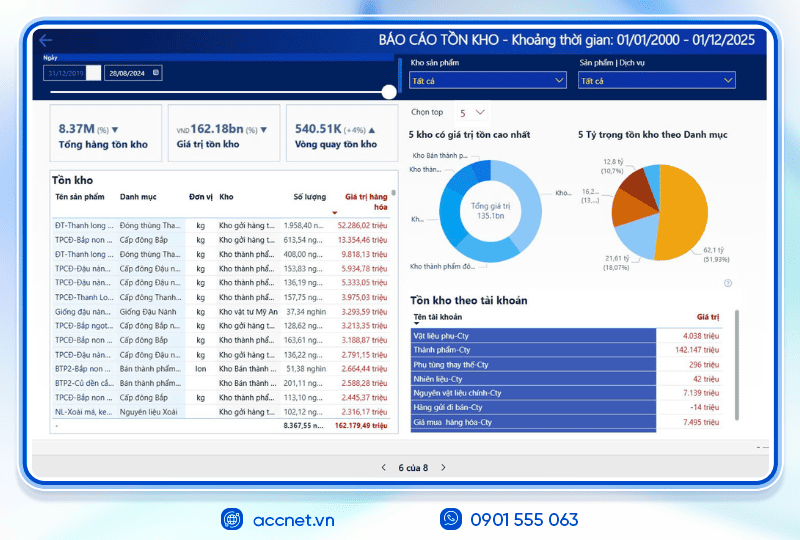

- Phân loại hàng hóa linh hoạt: Tạo mới danh mục theo nhu cầu; phân nhóm theo thuộc tính; thống kê doanh số, lãi gộp theo nhóm; mỗi mã hàng kèm đầy đủ thông tin tồn kho, tài khoản, giá vốn, thuế, phương pháp xuất kho.

- Quản trị kho đa dạng – kết nối thiết bị: Phần mềm quản lý kho AccNet ERP hỗ trợ QR code, barcode, thiết bị kiểm kê; quản lý tồn kho theo trạng thái (tài chính, vật lý, sẵn sàng bán); cho phép xuất kho theo hạn sử dụng, chuyển đổi đơn vị tính; hỗ trợ nhiều phương pháp tính giá xuất (BQGQ, FIFO, đích danh...).

- Quản lý tồn kho chính xác, đa chiều: Theo dõi theo màu sắc, kích thước, cấu hình, vị trí kho, mã lô; cho phép khai báo song song đơn vị đo lường, kiểm đếm; đối chiếu tồn kho thực tế với sổ sách.

- Tối ưu hiệu suất kho: Truy xuất nhanh hạn sử dụng, nguồn gốc hàng; tìm kiếm thông minh; quản lý định mức nguyên vật liệu; cập nhật tồn kho tự động theo đơn bán; cân đối hàng tồn toàn hệ thống, lưu lịch sử điều chuyển.

AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn.

- Phân tích tồn kho 24/7 trên cả desktop & mobile: AI liên tục cập nhật số liệu thực tế, cảnh báo khi hàng sắp thiếu hoặc tồn đọng quá lâu.

- Dự báo nhu cầu và rủi ro hàng hóa: Từ dữ liệu lịch sử, hệ thống đưa ra dự báo xu hướng nhập – xuất, giúp doanh nghiệp tối ưu kế hoạch mua hàng.

- Tra cứu tức thì chỉ trong vài giây: Tìm nhanh sản phẩm, số lượng tồn kho, công nợ liên quan, giá trị hàng hóa,… chỉ qua một thao tác trò chuyện với AI.

- Tự động hóa nghiệp vụ kho: Từ phiếu nhập, phiếu xuất đến kiểm tra tồn, hệ thống tự động hạch toán, đối chiếu và kết nối trực tiếp với báo cáo tài chính.

✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát”

- Tự động hóa đến 80% nghiệp vụ nhập – xuất – tồn, chuẩn hóa quy trình kho vận.

- AI hỗ trợ dự báo nhu cầu hàng hóa, cảnh báo tồn kho cận date hoặc ứ đọng.

- Đồng bộ dữ liệu kho theo thời gian thực, kết nối trực tiếp với tài chính – kế toán.

- Vận hành đa nền tảng trên desktop & mobile, tra cứu số liệu kho tức thì.

✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI

- Giảm đến 30% chi phí lưu kho nhờ tối ưu tồn và tự động hóa quy trình.

- Rút ngắn 50% thời gian kiểm kê và xử lý hàng hóa cận date.

- Increase 82% độ chính xác dữ liệu, giảm sai sót và thất thoát hàng hóa.

- Cải thiện hiệu suất dòng tiền nhờ kiểm soát chặt vốn lưu động bị “giam” trong kho.

ĐĂNG KÝ NHẬN DEMO NGAY

Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng

✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp

✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

Some other solution

- WMS-X (VTI Solutions): inventory Management, smart suggestions for using QR Code.

- 3S WMS / 3S iWAREHOUSE (ITG Technology): automated import/export/inventory QR Code/Barcode.

- Fast Business Online (FAST): ERP integrated QR Code in inventory management, purchasing, production, warehouse and inventory.

- AMIS WAREHOUSE (MISA): Supports multi-warehouse management, barcode scanning , data integration from the software MISA another.

The operation of warehouses tradition no longer meet the requirements of speed, accuracy , data management. Inventory management with QR Code is the modern solution to help businesses optimize processes, increase productivity, reduce errors and inventory control in a smart way.

In conjunction with warehouse management software as comprehensive as AccNet ERP, businesses can deploy QR Code effectively, easily track, manage , make decisions based on real-time data. This is a strategic move to help businesses , small upgrades, inventory management, preparation for the transition of comprehensive, optimized to operate in the era of 4.0.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET ERP

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: