Inventory is not only physical assets but also the key factors affect the cost, cash flow and operational performance of the business. Inventory management is lacking easily lead to a situation backlog capital, shortage of materials, or even loss no control over.

Therefore, construction of a process, inventory management, standard tuning efficiency is a top priority of many businesses when deploying the inventory accounting system professional. Particularly in the context of conversion of automation, the digitization process, inventory management will help businesses save resources, optimization of operation, ensuring transparency in financial reporting.

This article will help business understand process, inventory management what is the step by step implementation of specific application accounting solutions modern warehouses for inventory control efficiency.

1. Process management what is inventory?

Concept overview

Process of inventory management is the set of steps, procedures, tools to control the whole lifecycle of inventory – from the moment of warehousing, storage, inventory to stock or liquidation. The main objective is to ensure the goods are managed in the right quantity, of the right type, right time, right place – from it support to the production department, sales, accounting and operational efficiency.

Angle of view inventory accounting

From the perspective of accounting, this process is also important to:

- Establishment of accounting vouchers: voucher import – export inventory report, inventory,...

- Accounting exactly the accounting profession warehouse: standard circular 200 or circular 133.

- Analysis - assessment inventory turnover to serve the financial reporting, management reports.

The goal of the management process inventory

- Minimize the costs of storage, optimize cash flow: avoid excess or shortage of goods.

- Increase the efficient use of assets: release inventory slow rotation.

- Ensure accuracy for accounting data: support tax reporting, financial reporting.

- Increase the ability to react to market: forecast inventory in a timely manner to service large orders, unscheduled.

Outstanding benefits when standardized processes

- Reduce the risk of loss and erroneous data due to crafts.

- Increase personnel productivity, warehouse, and accounting.

- Increased ability to connect with the software, other management: ERP, CRM, financial accounting.

- To increase transparency, the reliability of the report – are important factors in internal auditing or call capital investment.

According to a survey by McKinsey (2023), the business process, inventory management is standardized, integrated management software have reduced the average 25-35% of the cost of operating the inventory each year.

Read more:

2. Detailed analysis process, inventory management step by step

Step 1. Determine the inventory level optimization (Reorder Point)

This is the first step, is also the foundation of the process of inventory management efficient. Determine the inventory level optimization will help your business to order the right time, avoid stock shortages or excess cause preserve capital.

The concept of norms inventory

- Inventory minimum (Minimum Stock Level): Threshold goods lowest to ensure uninterrupted operation.

- Inventory maximum (Maximum Stock Level): the Level of the maximum permitted for storage in the repository.

- Point of order-again (Reorder Point): When inventory reaches this level they need to plan extra income.

Formula for calculating the Reorder Point (ROP)

ROP = average Demand daily × delivery Time

For example:

- Daily needs: 100 products

- Delivery time: 5 days → ROP = 100 × 5 = 500 products

Model inventory management downloads

- EOQ (Economic Order Quantity): Determine the volume of order optimal.

- JIT (Just-In-Time): inventory Management minimum – products come to the right when needed.

Step 2. Process and warehousing of goods

Warehousing is the stage of the service first, directly affect the quality of accounting data warehouse.

The standard steps when entering inventory in process, inventory management

- Check accompanied by receipts (invoices, orders,...)

- Check the quantity and quality of the actual goods.

- Recorded on the software/form warehousing.

- Establishment receipt – voucher mandatory accounting.

Accounting recorded professional warehousing

Circular 200:

- Debit TK 152, 153, 155 (for custom orders)

- Credited TK 331 (pay NCC), 111/112 (if already paid)

Form used

- Receipt (Form no. 01 – VT)

- Minutes, check the quality of the goods

- Contracts, invoices comes (electronic storage makes it easy to check out control)

Step 3. Storage, storage, organized warehouse

A warehouse system good will minimize the risk of damage, losses and increase efficiency export – import.

Principles for efficient storage

- 5S: screening – sort – Clean – care – ready

- FIFO – FEFO: Export in order to enter or limited use.

Encoding goods

- Use code SKU (Stock Keeping Unit) to distinguish goods.

- App barcode or QR code to scan and inventory fast.

Sorting warehouse

- Split by region: import – queue check – Restaurant reach – Order error.

- The ABC model: A (high value, quantity less) → need strict control.

Step 4. Track inventory inventory periodically in process inventory management

This step is important helps to detect the difference between the inventory fact, inventory books.

The frequency of inventory

- Depending on the particular industry: inventory every week, month, quarter, or year.

- Can inventory extraordinarily when there are signs of loss.

How to inventory

- Compare actual figures with the software or the books.

- Recorded deviations, making inventory (form BB-03/VT).

Handling discrepancies

- If excess: Recorded an increase in assets, handle according to the financial regulation.

- If missing/broken: Set the minutes, record the decrease in asset accounting to cost management, or responsibility.

Step 5. Export warehouse - recorded costs in process inventory management

Stage production inventory should record the exact purpose used to serve the management accounting and finance.

Types of stock common

- Export warehouse for production

- Export inventory to sales

- . The internal drain, prototype

Method recorded the price of capital

- Weighted average

- First in – first out (FIFO)

- Purpose of the

Accounting accounting

- Debit TK 621/627/641/642

- Credited TK 152/155

Flow chart template: accounting software can draw flow charts, and processes. the auto – up operation manually.

Read more: Hướng dẫn quản lý sản phẩm hoàn thiện trước khi đưa vào kho lưu trữ

Step 6. Inventory report, data analysis

Reporting is the last part in the process of inventory management, but the role analysis, decision support.

Report required

- Inventory report details according to the code order, shipment term use

- Synthesis report the first viable states – import – export – survive the end

- Report inventory turnover

Indicators to track

Inventory Turnover Ratio = cost of goods sold / inventory value average

- If low: multiple inventories, cash flow detention

- If high: rotate well, but runs the risk of missing goods

Tool support

- Power BI, Excel Dashboard

- Accounting software can analysis module repository (AccNet Inventory, Bravo ERP,...)

3. Common mistakes when managing inventory

Many businesses when not standardized processes, inventory management often entangled to the mistake follows:

- Do not set the inventory levels, safety → Easily lead to shortages of raw materials, production interruptions.

- Only the inventory on the books, not reality check → To variances, inventory, reporting deviations.

- Using Excel, masturbation, public, teen, real-time updates → No warnings inventory below the minimum, error prone input – output – inventory.

- Storage goods of clutter, do not apply coding → Difficult to access the fastest, easiest, confusion, waste workers.

According to the survey of Logistics Bureau (2023), 42% of businesses don't reach business objectives of inventory management less effective – the cause is mainly due process has not been digitized automation.

4. The role of accounting software inventory in the optimal process, inventory management

In the digital age, the use of accounting software inventory not only helps digitize processes, manage inventory but also bring productivity, accuracy superior to the manual method. This is the indispensable tool if the business wants to control inventory effectively, connect related departments.

Process automation inventory accounting

- From stitching import – export – inventory – report, all the data is recorded instantaneous, maximum reduction of errors due to human.

- Automatic calculation of the price of capital, inventory alert below safe levels.

- Sync information with financial accounting, sales, purchases to create the eco-system operation seamless.

Friendly interface, the operation easy to use

- Users do not need accounting expert deep still easy to manipulate.

- Interface decentralize role: inventory management, accounting, board of directors.

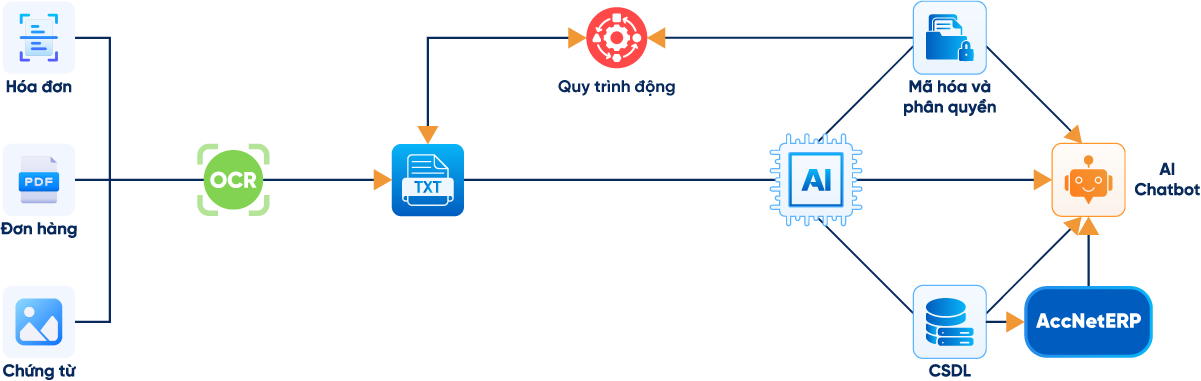

Privacy - access control

- Permission system clear, helps control access by each function.

- Log all activity to help trace quickly when there is a problem.

Analysis - the report in real time

- System chart is intuitive: inventory item code, the rotation of goods, inventory, slow-moving,...

- Easy to set up internal reporting service, audit or strategic decisions.

Flexible integration with other systems

- Connect with ERP, software sales, CRM or system electronic invoice.

- Data sync helps save time, reduce deviations between the parts.

For example: software AccNet Inventory of Lac Viet helps business inventory control, rotation stock from the warehouse – accounting in only 1 platform, helps reduce up to 40% of the cost of inventory, shorten the duration of the reported 60% compared with traditional way.

PHẦN MỀM QUẢN LÝ KHO ACCNET ERP TÍCH HỢP “TRỢ LÝ TÀI CHÍNH AI” Không chỉ là một phần mềm nhập – xuất thông thường, AccNet ERP chính là nền tảng quản lý kho thông minh, tích hợp thiết bị, kết nối dữ liệu, cảnh báo tức thời, giúp doanh nghiệp: AccNet ERP mở ra một bước tiến mới trong quản lý kho khi tích hợp trợ lý tài chính AI, giúp doanh nghiệp vận hành chủ động và ra quyết định chính xác hơn. ✅ Quản lý kho chủ động – Không còn “tồn kho ảo, thất thoát khó kiểm soát” ✅ Hiệu quả rõ rệt khi ứng dụng quản lý kho tích hợp AI ĐĂNG KÝ NHẬN DEMO NGAY Vui lòng điền các thông tin vào form chúng tôi sẽ liên hệ lại với bạn trong 24h làm việc.

✅ Demo miễn phí full tính năng ✅ Báo giá cá nhân hóa theo quy mô doanh nghiệp ✅ Tư vấn 1:1 cùng chuyên gia có nhiều kinh nghiệm

5. The modern trends in inventory management

Along with the development of technology, businesses can apply the new trend to improve efficiency, be more active in the process of inventory management/operations warehouse:

IoT application in inventory management

- Sensor positioning device helps to track location, temperature, humidity of goods in real time.

- Limited damage to the goods, especially in cold storage, pharmaceutical,...

QR code scanner - RFID

- Speed up inventory and limit confusion.

- Traceability of goods in a few seconds.

Artificial intelligence (AI) in forecasting inventory

- Analyze historical data to predict demand and inventory the future.

- Automatic suggestions the time of order entry, order volume fit.

Model repository (Smart Warehouse)

- App robot automatically in taking orders, shipping internally.

- Executive stock by threading the optimal move, reduce workers.

As reported by Statista 2024, there are more than 72% of business apply smart technology in inventory management recorded a performance increase of over 20%, reducing operating costs by 15% in just 1 year.

A process, inventory management basically, science is not only to help businesses control the goods but also the platform to enhance operational efficiency, financial decisions correct.

For those businesses that are in the phase of construction accounting solutions warehouse, standardizing processes, investment software is dedicated step strategy to:

- Reduce operating costs

- Increase financial transparency

- Enhance competitiveness

If your business is experiencing problems such as:

- Furniture warehouse escape, false data inventory

- Management by Excel discrete, not connected with accounting

- Report stock slow, difficult to control

Consider implementing accounting software dedicated warehouse AccNet Inventory to standardize processes, number conversion more efficient. Sign up experience accounting software inventory today to reach the optimal tool inventory according to the standard modern accounting.

CONTACT INFORMATION:

- ACCOUNTING SOLUTIONS COMPREHENSIVE ACCNET

- 🏢 Head office: 23 Nguyen Thi huynh, Ward 8, Phu Nhuan District, ho chi minh CITY.CITY

- ☎️ Hotline: 0901 555 063

- 📧 Email: accnet@lacviet.com.vn

- 🌐 Website: https://accnet.vn/

Theme: